Engine knocking noise is a metallic pinging or rattling sound caused by abnormal combustion (detonation) or worn mechanical parts. Common fixes: use higher-octane fuel, clean carbon buildup, replace spark plugs, or repair bottom-end bearings. DIY cost: $20–$400. Shop cost: $200–$3,500.

Tuesday, 7:15 a.m., 38 °F in the shop—my coffee hadn’t even cooled when a 2014 Silverado 5.3 rattled in on the flat-bed. Owner’s face looked like he’d seen a ghost. “She’s knocking like a Jehovah’s Witness on Red Bull,” he said. I fired it up—sure enough, a hollow knock-knock-knock from the valley that doubled with RPM. Ten minutes later I had the oil pan off and my bore scope shoved into cylinder #7: spun rod bearing, crank journal blue, metal glitter in the pan. Customer’s question: “Is it toast?” My answer: “Not toast—just expensive bread.” That’s the moment I decided to write this guide. If you can catch a engine knocking noise early, you can save the crank, the wallet, and maybe the marriage.

What Engine Knocking Noise Actually Is

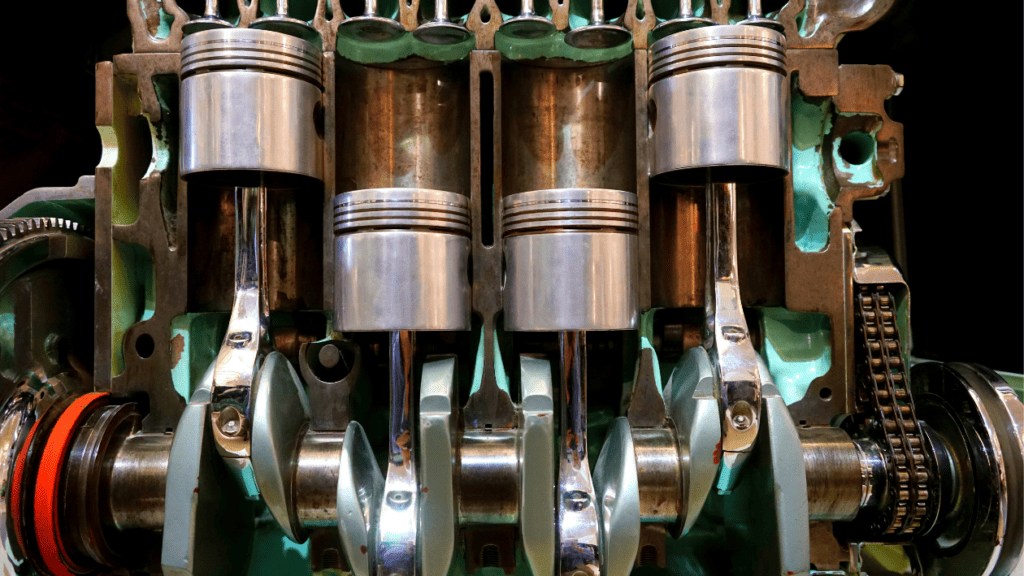

Knocking, pinging, detonation—same family, different last names. Detonation is when the air-fuel mixture explodes instead of burning smoothly. The pressure spike hammers the piston crown like a sledgehammer, creating that metallic ping. Mechanical knock (rod or main bearing) is deeper, heavier, and climbs with engine speed. One can ruin your afternoon; the other can ruin your engine.

Rule of thumb: Light pinging on acceleration = ignition or fuel issue. Deep knock at idle that gets faster with RPM = bottom-end mechanical. Stethoscope on the pan will tell you in 30 seconds.

Causes: From 87-Octane Swill to Spun Bearings

| Type of Knock | Sound Description | Common Cause | Quick Test |

|---|---|---|---|

| Detonation / Pinging | Marbles in a tin can | Low octane, carbon buildup, over-advanced timing | Retard timing 2°, add 91-octane, noise gone? |

| Rod Bearing Knock | Heavy hollow thud | Oil starvation, 5W-20 in a 150 k-mile truck, worn bearing | Short out cylinders one at a time—noise disappears on bad cylinder |

| Piston Slap | Wooden ruler on desk | Cold aluminum piston-to-wall clearance (GM 3.1/5.3 famous) | Goes away when engine hits 120 °F |

| Carbon Knock | Random metallic click | Glob of carbon glows red, pre-ignites mixture | Top-engine cleaner + Italian tune-up |

Real-World Example

Last month a 2018 Subaru WRX showed up with “weird pinging under boost.” Scan tool showed -3 ° knock correction. Customer had filled 87-octane because “premium is a scam.” Drained the tank, added 93 plus a bottle of Royal Purple Max-Boost, reflashed ECU to stock—pinging gone. Total cost: $78 and a lesson in thermodynamics.

Diagnose Engine Knocking Noise in 15 Minutes

Safety first: Eye protection, gloves, cold engine. Remove serpentine belt—eliminates accessories.

Stethoscope sweep: Probe valve cover, lower pan, front cover. Knocks in the pan = bottom end. Knocks on head = valvetrain or carbon.

Cylinder kill test: With engine idling, unplug coils one at a time. If knock disappears, you’ve found the guilty cylinder.

Scan for KR: Knock Retard (KR) over 3 ° means the PCM is already pulling timing. Look at freeze-frame—was it under load? Hot? Cheap fuel?

Oil inspection: Silver glitter = bearing material. Copper flakes = rod bearings. Black chunks = timing chain guides.

When to Stop: If oil pressure is below 8 psi at hot idle, shut it off immediately. Continuing will turn a $400 bearing job into a $4,000 short-block.

Still unsure? Learn about engine knock diagnosis, knocking sound engine, detonation noise to cross-check sounds.

DIY Fixes Ranked by Difficulty

Easy: Fuel & Carbon (1–2 hrs, $20–$80)

- Drain one gallon of fuel, refill with 93-octane or add octane booster (Torco, Boostane).

- Remove air tube, spray CRC Intake Valve Cleaner into throttle body while a helper holds 2,000 RPM.

- Install new OEM-spec spark plugs gapped to 0.043 in (check under-hood sticker).

- Clear adaptions with scan tool, road test 10 min WOT pull to blow out carbon.

Pro tip: On GDI engines (most 2012+), carbon on intake valves is the #1 cause of pinging. Run a can of CRC every 10 k miles—dealer charges $275 for the same 15-minute job.

Moderate: Knock Sensor & Timing (2–3 hrs, $60–$180)

2005–2014 GM trucks love to set P0327 when water collects under the sensor. Part # is 12614969, torque to 18 ft-lbs with a dab of dielectric grease. While you’re there, bump ignition timing tables back to stock if somebody got “tuner happy.”

Difficult: Rod Bearings (8–12 hrs, $250–$400 DIY)

Engine stand or remove K-member—no shortcuts. Wear safety glasses; rod bolts are 200 °F during removal.

- Remove oil pan (expect 14 mm bolts, 10 ft-lbs).

- Plastigage each journal. GM 5.3 spec: 0.0008–0.0022 in clearance.

- Replace with Federal-Mogul 4663A bearing set—$48 on RockAuto.

- Torque new ARP 2000 rod bolts to 20 ft-lbs + 55 ° (use angle gauge).

- Prime oil system with a $35 primer tool before first start.

If the crank is scored, polish with 400-grit emery and oversized bearings (0.001 in). Beyond 0.003 in, you need a crank kit—time to call a machine shop.

Real-World Cost Breakdown

| Repair | DIY Parts | Shop Price | Your Savings |

|---|---|---|---|

| Octane booster + plugs | $42 | $160 | $118 |

| Knock sensor (GM truck) | $65 | $325 | $260 |

| Rod bearings (one side) | $280 | $1,800 | $1,520 |

| Short-block assembly | $2,400 | $5,500 | $3,100 |

Add $150–$250 for machine-shop crank grind if you’re past 0.003 in. Always replace oil pump ($89 Melling M295) while pan is off—cheap insurance.

Tools & Materials Shopping List

Must-Have

- Mechanic’s stethoscope – $14 on Amazon

- 14 mm socket, 3/8-drive – Craftsman 9-44838

- Torque wrench, 10–150 ft-lbs – Tekton 24335 – $79

- Plastigage – $6

- Oil-primer tool – Melling P-55 – $35

Nice-to-Have

- Bore-scope – Depstech 5.0 MP – $49

- Angle torque gauge – $22

- Engine support bar – $89 (rent free at AutoZone)

FAQ—Real Questions from Real Customers

Can I drive with a light engine knocking noise?

If it’s detonation ping, yes—fill 93-octane and drive gently to the parts store. If it’s a deep rod knock, every mile turns a $400 bearing job into a $4,000 crate engine. Tow it.

Does seafoam fix engine knock?

Seafoam or CRC GDI cleaner will remove carbon that causes pinging. It will NOT fix a spun bearing. Know which knock you have first.

How much does it cost to fix engine knocking noise at a dealer?

Carbon de-carb service: $275–$400. Knock sensor: $350–$450. Rod bearings (pull pan only): $1,800–$2,200. Full short-block: $5,000–$7,500.

Will thicker oil stop rod knock?

20W-50 might quiet it for a week, but it’s a Band-Aid on a bullet wound. Fix the clearance; don’t mask it.

Is low oil pressure related to knock?

Absolutely. Low oil pressure starves bearings, causing metal-to-metal contact and the dreaded hammering sound. Check pressure with a mechanical gauge before anything else.

Can bad gas cause engine knocking noise?

Yup. 87-octane in a high-compression or turbo engine will detonate faster than popcorn. Always run the grade listed on the filler door—no exceptions.

How long do rod bearings last?

With 5W-30 changed every 5 k, OEM bearings easily see 200 k miles. Stretch oil to 10 k with cheap dino juice and you’ll meet me at 120 k with a knock.

What’s the cheapest first step?

Fill two gallons of 93-octane, add one bottle of octane booster, and test-drive hard up a hill. If the ping vanishes, you just saved hundreds.