By ASE-Certified Master Automotive Technician

A Rainy Tuesday Misfire Mystery

It was 7:45 AM on a rainy Tuesday when Sarah pulled into my shop in her 2016 Honda Civic, the check engine light blinking like a frantic strobe light. “It’s shaking like crazy,” she said, her voice filled with concern. “I’m afraid to drive it home.”

I’ve seen this scenario hundreds of times over my 15 years as an ASE-certified technician. A blinking check engine light almost always means a cylinder misfire, and Sarah’s Civic was exhibiting all the classic symptoms: rough idle, lack of power, and that distinct shaking that tells you something’s seriously wrong under the hood.

After hooking up my diagnostic scanner, the code P0303 popped up immediately – cylinder 3 misfire detected. This is one of the most common issues I encounter, yet it can stem from dozens of different causes. What followed was a methodical diagnostic process that I’m about to share with you, along with all the tricks I’ve learned from diagnosing and fixing countless cylinder misfires over the years.

Quick Answer: What is a Cylinder Misfire?

A cylinder misfire occurs when the fuel-air mixture in one or more engine cylinders fails to ignite properly or at all. This can be caused by issues with the ignition system, fuel system, or mechanical problems within the engine. Common symptoms include rough idle, reduced power, poor fuel economy, and a check engine light that may flash intermittently.

Understanding Cylinder Misfires

Before diving into the nitty-gritty of diagnosis and repair, let’s establish what exactly happens during a cylinder misfire. In a properly functioning engine, each cylinder goes through four strokes: intake, compression, power, and exhaust. During the power stroke, the spark plug ignites the fuel-air mixture, forcing the piston down and generating power.

When a misfire occurs, this combustion process is disrupted or fails entirely. The result is an engine that’s not firing on all cylinders, literally. This imbalance causes the rough running and loss of power that drivers experience.

Types of Misfires

- Random misfire (P0300): Multiple cylinders misfiring randomly

- Single cylinder misfire (P0301-P0308): A specific cylinder is misfiring

- Multiple cylinder misfire: Two or more specific cylinders are misfiring

Common Causes of Cylinder Misfires

In my experience, cylinder misfires typically fall into three categories: ignition-related, fuel-related, or mechanical. Let’s break down each category with specific examples I’ve encountered in the shop.

Ignition System Issues

The ignition system is responsible for creating the spark that ignites the fuel-air mixture. Problems here are the most common cause of misfires, accounting for approximately 70% of cases I see.

Spark Plug Problems

Worn or damaged spark plugs are the number one culprit. I’ve seen spark plugs that were so worn they had a gap of over 0.080 inches (double the specification on most vehicles). I’ve also found plugs with cracked insulators, oil-fouled electrodes, and electrodes that were completely burned away.

Warning: Always use the exact spark plug specified by the manufacturer. I once had a customer install platinum plugs in a vehicle that required iridium plugs, resulting in persistent misfires. The vehicle’s ignition system was designed for the specific electrical properties of the recommended plug.

Ignition Coil Failure

Ignition coils transform the battery’s 12 volts into the thousands of volts needed to create a spark. When these fail, you’ll get either a weak spark or no spark at all. I’ve seen coils fail due to age, heat damage, and even oil leaks from valve cover gaskets.

For example, on many Ford vehicles from 2004-2012, the coil-on-plug design is notorious for failure. I’ve replaced countless coils on F-150s and Expeditions, with the most common failure being cylinder 4 and 8 due to their location at the back of the engine where heat builds up.

Learn more about [ignition coil failure](ignition-coil-failure) and how to diagnose it properly.

Distributor or Distributor Cap Issues

On older vehicles, the distributor and cap can cause misfires. I’ve seen caps with carbon tracks, cracked rotors, and worn distributor shafts that cause timing issues. If you’re working on a vehicle with a distributor (mostly pre-2000 models), always inspect these components carefully.

Fuel System Issues

If the ignition system checks out, the fuel system is the next logical place to look.

Fuel Injector Problems

Clogged or malfunctioning fuel injectors can cause a lean condition in a specific cylinder, leading to misfires. I’ve seen injectors clogged with debris, stuck open, or completely failed electrically.

A common issue I encounter on GM vehicles with the 3.8L V6 engine is injector failure. The plastic body of the injector can crack, causing fuel to leak externally or internally, leading to misfires and even hydro-lock if severe enough.

Fuel Pressure Problems

Low fuel pressure can cause random misfires across multiple cylinders. I’ve diagnosed this issue caused by failing fuel pumps, clogged fuel filters, and faulty fuel pressure regulators.

Mechanical Issues

These are the most serious and expensive causes of misfires, but thankfully they’re less common than ignition or fuel issues.

Compression Problems

Low compression in a cylinder can prevent proper combustion. I’ve found this caused by worn piston rings, burned valves, blown head gaskets, and even cracked cylinder heads.

I once had a 2005 Toyota Camry with a persistent cylinder 2 misfire that wouldn’t go away despite replacing all ignition and fuel components. A compression test revealed cylinder 2 had only 80 PSI compared to 180 PSI in the other cylinders. The culprit was a burned exhaust valve, requiring cylinder head removal and repair.

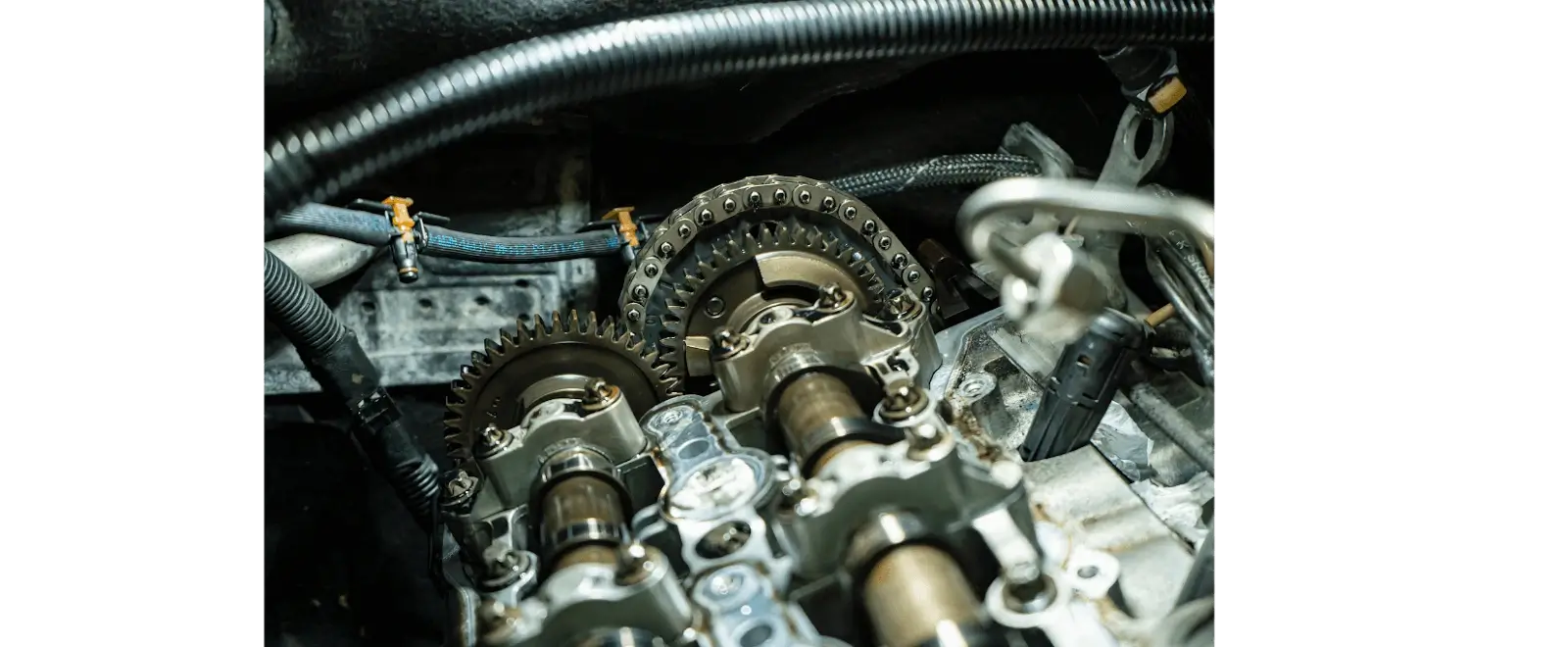

Timing Issues

Incorrect valve timing can cause misfires. I’ve seen this caused by stretched timing chains, jumped timing belts, and faulty variable valve timing (VVT) systems.

On many Honda vehicles from 2006-2011, the VTC actuator can fail, causing a rattling noise on startup and intermittent misfires until oil pressure builds up. This is a known issue with Technical Service Bulletins (TSBs) available from Honda.

Diagnosing a Cylinder Misfire

Now that we understand the potential causes, let’s walk through the diagnostic process I use in the shop. This systematic approach will help you pinpoint the exact cause of your misfire without replacing unnecessary parts.

Step 1: Scan for Trouble Codes

Connect an OBD-II scanner and retrieve all stored codes. Pay special attention to codes P0300 through P0308, which indicate misfires.

- P0300: Random/Multiple Cylinder Misfire Detected

- P0301: Cylinder 1 Misfire Detected

- P0302: Cylinder 2 Misfire Detected

- P0303: Cylinder 3 Misfire Detected

- P0304: Cylinder 4 Misfire Detected

- P0305: Cylinder 5 Misfire Detected

- P0306: Cylinder 6 Misfire Detected

- P0307: Cylinder 7 Misfire Detected

- P0308: Cylinder 8 Misfire Detected

A single cylinder misfire code (like P0302) points to an issue affecting just that cylinder, while a P0300 suggests a problem affecting multiple cylinders or the engine as a whole.

Step 2: Analyze Freeze Frame Data

Review the freeze frame data captured when the code was set. This snapshot can provide valuable clues about the conditions when the misfire occurred, such as engine speed, load, and temperature.

If the misfire occurred at high RPM under heavy load, I’d suspect ignition issues. If it happened at idle with low load, fuel delivery problems are more likely.

Step 3: Visual Inspection

Perform a thorough visual inspection of the ignition system. Look for cracked spark plug wires, oil on spark plugs or coils, damaged coil boots, and loose connections.

I once found a mouse had chewed through a spark plug wire on a truck that had been parked for a few weeks. The misfire was obvious once I saw the wire damage.

Step 4: Swap Components

If you have a single cylinder misfire, try swapping components with another cylinder to see if the misfire follows the part.

For example, if you have a P0302 (cylinder 2 misfire), swap the ignition coil from cylinder 2 with the one from cylinder 3. Clear the codes and drive the vehicle. If the code changes to P0303, you’ve confirmed the coil is faulty.

The same technique works for spark plugs and fuel injectors on many vehicles.

Step 5: Check Fuel Delivery

If the ignition system checks out, it’s time to look at fuel delivery. Connect a fuel pressure gauge and compare the reading to specifications in your service manual.

For most modern vehicles, fuel pressure should be between 35-65 PSI, but this varies significantly by manufacturer. Always check the specific requirements for your vehicle.

If pressure is low, the issue could be a clogged fuel filter, weak fuel pump, or faulty fuel pressure regulator.

Step 6: Perform a Compression Test

If you’ve ruled out ignition and fuel issues, it’s time to check engine mechanical health with a compression test.

Most healthy engines should have compression between 150-200 PSI, with variation between cylinders not exceeding 10-15%. If one cylinder has significantly lower compression, you’ve likely found your culprit.

Remember to disable the fuel system and ignition before performing this test to prevent fuel from being sprayed into the cylinders and to avoid accidental ignition.

Fixing Common Cylinder Misfire Issues

Once you’ve identified the cause of your misfire, it’s time to fix it. Here are detailed instructions for the most common repairs I perform in the shop.

Replacing Spark Plugs

Replacing spark plugs is one of the most straightforward maintenance tasks, but there are some critical details to get right.

Tools Needed:

- Spark plug socket (typically 5/8″ or 13/16″)

- Ratchet and extension

- Spark plug gap tool

- Torque wrench

- Dielectric grease

- Anti-seize compound (if required by manufacturer)

Ensure the engine is completely cool. Removing spark plugs from a hot engine can damage the aluminum threads in the cylinder head.

Carefully remove the ignition coils or spark plug wires. Label them if necessary to maintain proper firing order.

Blow out the spark plug wells with compressed air to remove any debris that could fall into the cylinder when the plug is removed.

Remove the old spark plugs using the spark plug socket and extension. Turn counterclockwise to loosen.

Check the gap on the new spark plugs using a gap tool. Most modern plugs come pre-gapped, but always verify. The gap specification is typically found on a sticker under the hood or in the owner’s manual.

Apply anti-seize to the threads only if specified by the manufacturer. Some plugs come with a special coating that makes anti-seize unnecessary.

Install the new spark plugs by hand to avoid cross-threading. Once finger-tight, use a torque wrench to tighten to the manufacturer’s specification. This is typically 13-18 ft-lbs for aluminum heads, but always verify for your specific vehicle.

Critical Warning: Over-tightening spark plugs can damage the threads in the cylinder head, leading to expensive repairs. Under-tightening can cause poor heat transfer and misfires. Always use a torque wrench.

Apply a small amount of dielectric grease to the inside of the coil boot or spark plug wire boot to prevent moisture intrusion and ensure easy removal next time.

Reinstall the ignition coils or spark plug wires, ensuring they’re fully seated and secure.

Replacing Ignition Coils

Ignition coil replacement varies significantly by vehicle design. Here’s a general procedure for coil-on-plug systems, which are most common in modern vehicles.

Tools Needed:

- Ratchet and socket set

- Torque wrench

- Electrical contact cleaner

- Dielectric grease

Disconnect the negative battery terminal to prevent accidental electrical discharge.

Locate the faulty ignition coil. If you’re unsure which one is failing, refer to your diagnostic work or the stored trouble code.

Disconnect the electrical connector from the coil. Most have a locking tab that must be pressed before pulling the connector off.

Remove the mounting bolt(s) securing the coil. On many designs, there’s a single 8mm or 10mm bolt.

Carefully pull the coil straight up and out of the spark plug well. Sometimes they can be stuck due to heat and time. Gently twisting while pulling can help.

Inspect the coil boot and spring. If the boot is damaged or the spring is corroded, replace the entire coil assembly.

Clean the area around the spark plug well with compressed air and electrical contact cleaner.

Apply a small amount of dielectric grease to the inside of the new coil boot.

Install the new coil by pushing it straight down until it’s fully seated on the spark plug.

Reinstall the mounting bolt(s) and tighten to the manufacturer’s specification. This is typically around 7-10 ft-lbs, but check your service manual.

Reconnect the electrical connector until it clicks into place.

Reconnect the battery and start the engine to verify the repair.

Cleaning Fuel Injectors

Sometimes, a clogged fuel injector can be cleaned rather than replaced. Here’s how I approach this in the shop.

Tools Needed:

- Fuel injector cleaning kit

- Ratchet and socket set

- Fuel line disconnect tool

- Safety glasses and gloves

Safety Warning: You’ll be working with the fuel system, which is under pressure. Always wear safety glasses and gloves, work in a well-ventilated area away from open flames or sparks, and relieve fuel pressure before beginning any work.

Relieve fuel pressure by locating the fuel pump fuse or relay, starting the engine, and letting it run until it stalls. Crank the engine for a few seconds to ensure all pressure is relieved.

Disconnect the fuel line at the fuel rail using the appropriate disconnect tool. Have a rag ready to catch any residual fuel.

Connect the cleaning kit adapter to the fuel rail.

Fill the cleaning kit canister with the appropriate fuel injector cleaner.

Pressurize the system according to the cleaning kit instructions.

Start the engine and let it run on the cleaning solution for the time specified in the kit instructions (typically 10-15 minutes).

After the cleaning cycle is complete, shut off the engine and disconnect the cleaning kit.

Reconnect the fuel line and reinstall the fuel pump fuse or relay.

Start the engine and check for proper operation and any leaks.

Cost Analysis: DIY vs. Professional Repair

One of the most common questions I get from customers is whether they should tackle a misfire repair themselves or have a shop do it. Let’s break down the costs for common misfire repairs.

Spark Plug Replacement

| Vehicle Type | DIY Cost | Professional Cost | Difficulty |

|---|---|---|---|

| 4-Cylinder (Easy Access) | $20-50 (parts only) | $80-150 | Easy |

| 4-Cylinder (Difficult Access) | $20-50 (parts only) | $150-250 | Moderate |

| V6/V8 (Easy Access) | $30-80 (parts only) | $120-200 | Moderate |

| V6/V8 (Difficult Access) | $30-80 (parts only) | $200-400 | Difficult |

Ignition Coil Replacement

| Vehicle Type | DIY Cost | Professional Cost | Difficulty |

|---|---|---|---|

| Single Coil (Easy Access) | $50-120 (parts only) | $120-250 | Easy |

| Single Coil (Difficult Access) | $50-120 (parts only) | $200-350 | Moderate |

| Coil Pack | $80-250 (parts only) | $200-400 | Moderate |

Fuel Injector Replacement

| Vehicle Type | DIY Cost | Professional Cost | Difficulty |

|---|---|---|---|

| Single Injector | $80-200 (parts only) | $250-450 | Moderate |

| Full Set | $300-800 (parts only) | $500-1,200 | Difficult |

Pro Tip: When to Replace in Sets

For spark plugs, always replace them as a complete set. For ignition coils, I recommend replacing only the failed coil unless you have a vehicle known for coil failures (like some Fords or BMWs), in which case replacing them all might save you future headaches.

For fuel injectors, if one fails due to age, the others aren’t far behind. Consider replacing them all if your vehicle has high mileage (over 100,000 miles).

Preventing Future Cylinder Misfires

While some misfires are unavoidable due to part failure, many can be prevented with proper maintenance. Here are my top recommendations based on 15+ years in the shop:

Follow the Manufacturer’s Maintenance Schedule

This might seem obvious, but I can’t tell you how many misfires I’ve diagnosed that were caused by neglected maintenance. Replace spark plugs at the recommended interval, not when they start causing problems.

For example, many modern vehicles have iridium plugs designed to last 100,000+ miles, but I’ve seen them fail at 60,000 miles due to poor fuel quality or oil consumption. If you know your vehicle burns oil or you use lower-quality fuel, consider replacing plugs more frequently.

Use Quality Fuel

Cheap, low-quality fuel can cause carbon buildup on valves and pistons, leading to hot spots that can cause misfires. It can also clog fuel injectors over time. I’ve seen vehicles that consistently ran discount brand fuel develop injector issues at half the mileage of vehicles that used top-tier gasoline.

Address Oil Leaks Promptly

Oil leaks onto spark plugs or ignition coils will cause misfires every time. I’ve seen countless valve cover gasket leaks that led to coil failures. The oil degrades the rubber boot on the coil, allowing voltage to leak instead of reaching the spark plug.

If you see oil around your spark plugs or coils, address the leak before it causes more expensive damage.

Keep Your Engine Cool

Overheating can cause all sorts of problems that lead to misfires, from warped cylinder heads to damaged sensors. I once had a customer who ignored a leaking radiator hose, which led to an overheating event that blew the head gasket and caused multiple cylinder misfires. The $30 hose replacement turned into a $2,000 cylinder head repair.

Frequently Asked Questions About Cylinder Misfires

Can I drive with a cylinder misfire?

I don’t recommend driving with a cylinder misfire, especially if the check engine light is flashing. A flashing check engine light indicates a catalyst-damaging misfire, meaning unburnt fuel is entering the exhaust system and can overheat and destroy the catalytic converter. A new catalytic converter can cost $1,000-3,000, so it’s much cheaper to address the misfire promptly.

If you must drive the vehicle a short distance, keep the engine speed low and avoid hard acceleration. The longer you drive with a misfire, the greater the risk of additional damage.

How much does it cost to diagnose a cylinder misfire?

Diagnostic fees vary by shop and location, but you can expect to pay $100-200 for a professional diagnosis. This typically includes code retrieval, visual inspection, and some basic tests. More involved diagnostics like compression tests or fuel pressure tests may cost extra.

Many shops will waive or reduce the diagnostic fee if you have them perform the repair, so it’s worth asking.

Will a cylinder misfire clear itself?

Sometimes a temporary misfire due to bad fuel or moisture can clear itself after driving for a bit. However, most persistent misfires caused by component failure will not clear on their own and require repair.

Even if the check engine light goes off, the code will remain stored in the computer for a certain number of drive cycles. A scanner can still retrieve this information to help diagnose the issue.

Can bad gas cause a cylinder misfire?

Absolutely. I’ve diagnosed numerous misfires caused by bad or contaminated fuel. Water in the fuel is a common culprit, as is fuel with a lower octane rating than required by the engine.

If you suspect bad gas, try filling up from a different station. If the misfire clears after a few miles of driving, you’ve likely found your culprit. Adding a quality fuel system cleaner can also help remove any contaminants.

How long does it take to fix a cylinder misfire?

The time required depends on the cause. A simple spark plug replacement might take 30 minutes on an easy-to-access engine or 2-3 hours on a transverse-mounted V6 where the rear bank is difficult to reach.

Ignition coil replacement typically takes 15-30 minutes per coil. Fuel injector replacement can take 1-2 hours per injector, and more serious issues like valve repairs can take 8+ hours and require engine disassembly.

Can a cylinder misfire damage the engine?

Yes, a persistent misfire can cause serious engine damage. Unburnt fuel can wash oil off the cylinder walls, causing increased wear. It can also contaminate engine oil, reducing its lubricating properties.

Most importantly, as mentioned earlier, a misfire can destroy the catalytic converter, which is an expensive repair. In severe cases, a misfire can lead to overheating and catastrophic engine failure.

Should I replace all spark plugs if only one cylinder is misfiring?

Yes, I always recommend replacing spark plugs as a complete set. Spark plugs wear at similar rates, so if one is failing, the others aren’t far behind. Additionally, different types or brands of plugs can have slightly different heat ranges and electrical properties, which can affect engine performance.

The cost difference between replacing one plug versus a full set is minimal compared to the labor involved, especially if you have to remove the same components again when another plug fails.

Putting It All Together

Cylinder misfires are one of the most common engine issues I encounter in the shop, but with a systematic approach, they’re usually straightforward to diagnose and repair. The key is to start with the simplest and most likely causes (spark plugs and ignition coils) before moving on to more complex issues like fuel delivery or mechanical problems.

For most DIY mechanics, fixing a cylinder misfire is a moderate difficulty repair that can save you hundreds of dollars compared to professional service. With the right tools and a methodical approach, you can tackle most misfire issues in a weekend afternoon.

Remember that while many misfires are simple fixes, some can indicate more serious underlying problems. Don’t hesitate to seek professional help if you’re uncomfortable with any aspect of the diagnosis or repair. The cost of professional help is always less than the cost of causing additional damage through improper repair.

From my perspective as a technician, the satisfaction of solving a misfire mystery and restoring an engine to smooth operation never gets old. Whether you’re tackling the repair yourself or bringing it to a trusted shop, understanding the causes and solutions for cylinder misfires will help you make informed decisions about your vehicle’s care.

Learn more about [cylinder misfire repair, single cylinder misfire, fix cylinder misfire](diagnose-engine-misfire, ignition-coil-failure, bad-spark-plugs) to expand your knowledge on this common automotive issue.