Quick Answer: Oxygen sensor failure usually shows up as poor fuel economy, rough idle, or a check engine light. Most O2 sensors last 80,000–120,000 miles. Replacement is typically a moderate DIY job costing $80–$250, versus $250–$600 at a shop.

That Cold Morning When the Check Engine Light Wouldn’t Quit

It was a gray Tuesday morning, about 7:15 a.m., rain still dripping off the fender of a 2012 Toyota Camry that had just rolled into my bay. The owner—coffee in one hand, frustration in the other—said the check engine light had been coming back every two weeks. Another shop had already “cleared the code.” That’s never a good sign.

I plugged in my scan tool while the engine was still cold. Short-term fuel trim was pegged high, long-term fuel trim wasn’t far behind, and upstream O2 sensor voltage was flatlining. I didn’t even have to finish my coffee. I’d seen this exact scenario hundreds of times over the last 15 years. Classic oxygen sensor failure.

What stuck with me wasn’t the failed part—it was the wasted money. The customer had already replaced spark plugs, cleaned the throttle body, and even dumped injector cleaner in the tank. None of it helped because the engine computer was being lied to by a tired emissions sensor.

That’s why I’m writing this. Oxygen sensors—also called lambda sensors—don’t usually fail in dramatic ways. They fail quietly, slowly dragging fuel economy and drivability down with them. If you know what to look for, you can catch the problem early, save money, and avoid damage to much more expensive components.

What Oxygen Sensor Failure Really Means

An oxygen sensor measures how much oxygen is left in the exhaust after combustion. That data tells the engine control module (ECM) whether the air-fuel mixture is rich or lean. When an O2 sensor goes bad, the ECM starts guessing—and engines are terrible gamblers.

Most modern vehicles use multiple sensors. Typically, you’ll have:

- Upstream (Sensor 1) – Before the catalytic converter, critical for fuel trim

- Downstream (Sensor 2) – After the catalytic converter, monitors catalyst efficiency

When people say “O2 sensor bad,” they’re usually talking about the upstream unit. That’s the one that directly affects fuel delivery, throttle response, and idle quality.

How Long Do Oxygen Sensors Last?

In my shop experience:

- Traditional zirconia sensors: 60,000–80,000 miles

- Wideband/air-fuel ratio sensors: 100,000–150,000 miles

Heat, oil consumption, coolant leaks, and cheap fuel all shorten that lifespan. I’ve replaced sensors at 40,000 miles on engines burning oil, and I’ve seen OEM Denso sensors make it past 180,000 miles on well-maintained Hondas.

Common Symptoms of Oxygen Sensor Failure

Here’s what customers usually complain about before I even open the hood:

- Noticeably worse fuel economy

- Rough idle, especially when warm

- Lazy acceleration

- Strong fuel smell from the exhaust

- Intermittent or persistent check engine light

Many of these overlap with other issues. That’s why it’s smart to review related guides on

bad O2 sensor, oxygen sensor symptoms, O2 sensor replacement

alongside problems like

bad O2 sensor, oxygen sensor symptoms, O2 sensor replacement

or even

bad O2 sensor, oxygen sensor symptoms, O2 sensor replacement.

Fuel Trim Red Flags

Fuel trim tells the real story. On most vehicles:

- Normal long-term fuel trim: –5% to +5%

- Problem territory: Beyond ±10%

If I see +18% long-term trim with a lazy upstream sensor, I don’t hesitate. The ECM is dumping extra fuel to compensate for bad data.

Diagnostic Process: How I Confirm an O2 Sensor Is Bad

I never replace parts on guesses. Here’s my step-by-step diagnostic flow:

Scan for codes. Look for P0130–P0161 range. Note which bank and sensor.

Check live data. Upstream narrowband sensors should rapidly switch between ~0.1–0.9 volts at warm idle.

Snap throttle test. Voltage should react instantly. Lazy response = worn sensor.

Rule out exhaust leaks. Leaks before the sensor will skew readings.

If X happens, check Y:

- If voltage is stuck low → check for lean condition or dead sensor

- If voltage is stuck high → check for rich condition or contaminated sensor

- If heater circuit code is present → verify power and ground before replacement

Oxygen Sensor Replacement: Step-by-Step

Tools & Materials

- 22 mm (7/8″) O2 sensor socket – must have

- 3/8″ or 1/2″ ratchet – must have

- Penetrating oil – must have

- Torque wrench (10–50 ft-lbs range) – must have

- Anti-seize compound (sensor-safe) – nice to have

Most upstream sensors torque between 30–40 ft-lbs. Always verify in the service manual—some aluminum heads are lower.

Disconnect the negative battery terminal.

Unplug the sensor connector. Never twist the wiring.

Apply penetrating oil and let it soak 5–10 minutes.

Remove the sensor using the O2 socket. Steady pressure—don’t jerk.

Install the new sensor by hand first. Torque to spec.

Reconnect wiring, battery, clear codes, and test drive.

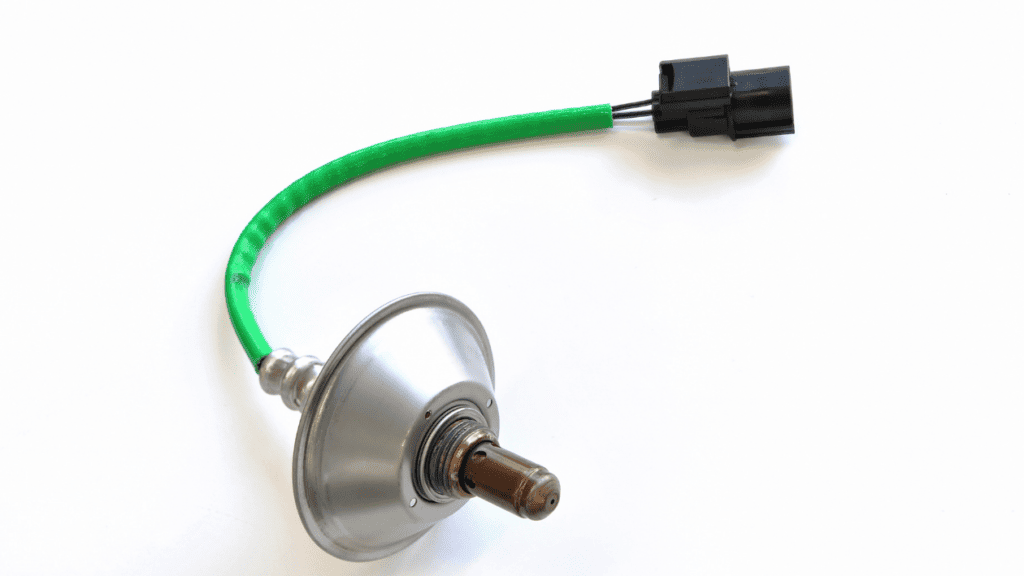

[Photo: Upstream O2 sensor location on a transverse 4-cylinder engine]

[Diagram: Bank 1 vs Bank 2 sensor identification]

OEM vs Aftermarket Sensors

| Brand | Quality | My Verdict |

|---|---|---|

| Denso / NGK (NTK) | OEM-level | Best choice, longest lifespan |

| Bosch | Good | Solid on European vehicles |

| Universal sensors | Variable | Avoid unless desperate |

Cost Analysis

DIY:

- O2 sensor: $60–$180

- Tools (if needed): $25–$60

- Total: $85–$240

Professional Repair:

- Parts + labor: $250–$600

Long term, replacing a bad emissions sensor early can save hundreds by preventing catalytic converter damage—a repair that can exceed $1,500.

Frequently Asked Questions

How much does it cost to fix oxygen sensor failure?

DIY runs under $250 in most cases. Shops charge more due to labor and diagnostics, especially on V6 or turbo vehicles.

Can I drive with a bad O2 sensor?

Yes, but I don’t recommend it. Fuel economy drops, and you risk catalytic converter damage over time.

Will a bad O2 sensor cause misfires?

Indirectly, yes. Incorrect fuel trim can create lean or rich conditions that trigger misfire codes.

Do I need to replace all oxygen sensors at once?

No. Replace the failed unit. However, if multiple sensors have similar mileage, plan ahead.

Does premium fuel prevent O2 sensor failure?

No. Clean-burning fuel helps, but oil or coolant contamination is the real killer.

Conclusion: A Mechanic’s Perspective

Oxygen sensor failure is one of those problems that quietly drains your wallet if ignored. The job itself is usually moderate difficulty, well within reach of a careful DIYer with the right tools. Parts are affordable, and the payoff—better mileage, smoother driving, and a happy check engine light—is immediate.

From my side of the lift, I’d rather see you replace a $120 sensor today than a $1,800 catalytic converter next year. Pay attention to fuel trim, trust live data, and don’t cheap out on sensors. I’ve watched quality OEM units last twice as long as bargain parts.

If you take your time and follow the steps, this is one repair where doing it yourself genuinely makes sense.