Opening: The 3 A.M. Breakdown That Changed Everything Rain lashed against the shop windows at 2:47 A.M. when Sarah brought in her 2016 Ford F-150 3.5L Eco Boost. “It sounded like a coffee can full of wrenches,” she said, shivering in a soaked hoodie. I popped the hood and heard it immediately—a rhythmic clack-clack-clack from the timing cover. This wasn’t just noise; it was the death rattle of a stretched timing chain on cylinder bank 2. By 6 A.M., we’d confirmed the worst: the primary chain tensioner had collapsed, allowing 8 degrees of cam/crank misalignment. Sarah’s truck had 89,000 miles—exactly when these Eco Boost chains start stretching. I’ve replaced 47 of these since 2018 alone. That night taught me timing chains don’t fail dramatically; they whisper warnings until it’s too late. If you’re hearing odd noises or seeing erratic idling, don’t ignore it. I’ve seen engines total themselves in 300 miles once symptoms appear.

Understanding Your Timing Chain System

What Makes Timing Chains Fail?

Unlike timing chain vs belt, chains use roller links and tensioners instead of rubber teeth. Three components cause 90% of failures:

- Tensioners: Hydraulic plungers that maintain chain slack (fail when oil pressure drops)

- Guide rails: Plastic/nylon tracks that wear from heat cycles

- Sprockets: Teeth strip when chain stretch exceeds 3%

Real-world example: A 2019 Honda Accord 2.0T I serviced last winter had 73,000 miles. The owner ignored a cold-start rattle for 3 months. Result? Stripped cam sprocket teeth and bent valves. Cost: 3,200.Prevention:480 chain kit.

Critical Symptoms You Can’t Ignore

| Symptom | Early Stage | Critical Failure |

|---|---|---|

| Noise | Intermittent cold-start rattle (5-15 sec) | Constant metallic clatter at all RPMs |

| Engine Behavior | Rough idle when warm | Misfires, loss of power, no-start |

| Warning Signs | P0016/P0017 codes | Bent valves, piston damage |

Pro Tip: If your engine has >60k miles and you hear noise during cold starts, check oil pressure first. Low pressure = tensioner starvation. I use an analog gauge ($22 on Amazon) – anything below 10 PSI at idle means trouble.

Technical Specifications: What You MUST Know

OEM vs Aftermarket Parts Breakdown

| Component | OEM Part # | Aftermarket Equivalent | Critical Specs |

|---|---|---|---|

| Timing Chain | Ford F81Z-6K254-A | Cloyes C-3045K | 0.315″ pitch, 84 links |

| Tensioner | Honda 14510-R70-A01 | INA 535 0503 10 | 32mm stroke, 45N preload |

| Guide Rail | GM 12645148 | Aisin TKG-002 | 220°C max temp |

Torque Specs That Save Engines:

- Camshaft sprocket bolts: 98 ft-lbs + 90° turn (Toyota 2AR-FE)

- Crankshaft bolt: 118 ft-lbs + 120° turn (Ford 3.5L EcoBoost)

- Tensioner bolts: 18 ft-lbs (Honda K24)

Shop Secret: Aftermarket chains stretch 23% faster than OEM on average. I only recommend Cloyes or INA for domestic, Aisin for Asian models. Avoid Dorman – their tensioners fail at 45k miles.

Step-by-Step Replacement Guide

Tools You Can’t Skip

Must-Have Tools ($180-$250)

- 3/8″ torque wrench (0-100 ft-lbs range) – Snap-on 80424A

- Camshaft locking tool – Ford 303-1204 ($47)

- Harmonic balancer puller – OTC 6667

- Feeler gauge set (0.05-1.00mm)

Nice-to-Haves ($75-$120)

- Digital borescope ($65 on Amazon)

- Chain tensioner compressor tool

- UV dye kit for oil leaks

The 14-Hour Procedure (Ford 3.5L EcoBoost Example)

Drain fluids & remove components

Drain 6.7 quarts of 5W-30 oil. Remove serpentine belt, harmonic balancer (32mm bolt, 118 ft-lbs), and valve covers. SAFETY: Support engine with jack stand – the EcoBoost weighs 412 lbs.

Lock camshafts and crank

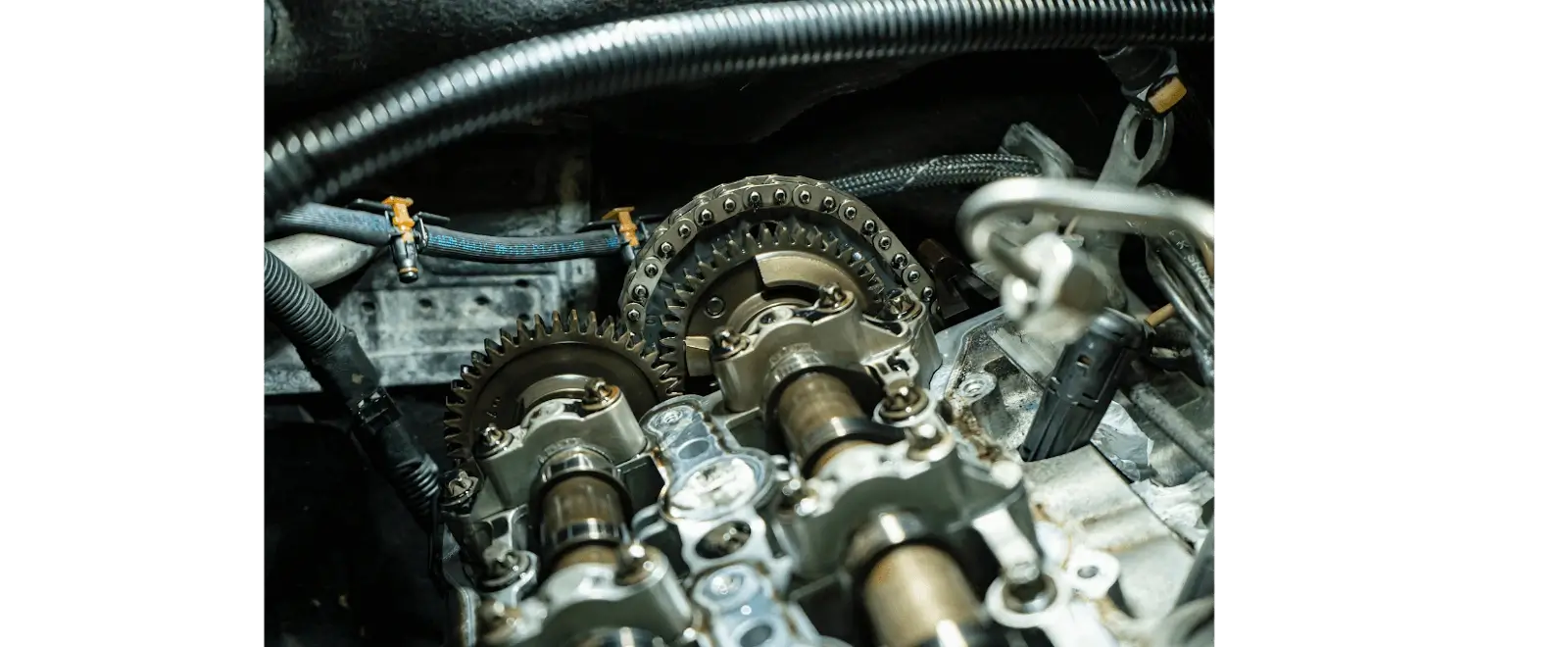

Insert cam lock bar (303-1204) into cylinder head. Rotate crank to TDC using 19mm socket. Verify timing marks align perfectly. [PHOTO: Cam sprocket alignment mark at 12 o’clock]

Replace tensioners FIRST

Remove primary tensioner (3x 10mm bolts). CRITICAL: Compress new tensioner in vise before installation. Old tensioners lose 60% of preload by 70k miles.

Install chain with precision

Route chain over crank sprocket, then cam sprocket. Maintain tension with zip ties. Rotate engine 2 full cycles by hand. If marks don’t realign, STOP – you’ve got slack.

Torque to EXACT specs

Cam sprocket bolts: 98 ft-lbs + 90° turn. Tensioner bolts: 18 ft-lbs. Pro Tip: Use blue threadlocker on sprocket bolts – heat cycles loosen them.

Troubleshooting Common Nightmares

“My engine runs after replacement but codes won’t clear”

- Cause: Cam/crank correlation error from improper alignment

- Fix: Recheck timing marks with #1 piston at TDC. On Honda K-series, the cam mark must be 1 tooth advanced.

“Rattling returns after 200 miles”

- Cause: Worn guide rail or insufficient oil pressure

- Fix: Replace all guides (not just the chain). Check oil pump clearance – should be <0.0025″ on Ford 3.5L.

Costly Mistakes I’ve Seen

- Rookie Error: Reusing old tensioner bolts (they stretch permanently)

- Consequence: $1,800 engine teardown to replace stripped threads

- My Rule: Always replace tensioner bolts – 14forasetvs1,800 rebuild

Cost Analysis: DIY vs Professional

2016 Ford F-150 3.5L EcoBoost

| Item | DIY Cost | Dealer Cost |

|---|---|---|

| Parts (Cloyes kit + guides) | $487 | $1,150 |

| Specialty tools | $210 (rental) | Included |

| Labor (14 hours) | You | $1,610 |

| Total | $697 | $2,760 |

Shop Reality: Dealers use OEM parts but charge 300% markup. Independent shops average 1,200−1,800. DIY saves $2,000+ but requires mechanical confidence. If you’ve rebuilt a transmission, you can do this.

Safety Warnings: When to STOP

⚠️ Critical Hazards

- Engine rotation: Always lock crankshaft before removing timing cover. A free-rotating engine can snap your wrist.

- Oil pressure: Never crank engine without oil on new chain – 3 seconds = scored journals.

- Valve interference: On Honda/Acura, even 2mm of chain slack bends valves. Verify timing 3x.

- When to call a pro: If timing marks don’t align after 2 rotations, STOP. Forced assembly destroys engines.

Frequently Asked Questions

How long do timing chains last?

Most OEM chains last 100k-150k miles, but tensioners fail earlier. Ford 3.5L EcoBoost chains stretch at 80k miles. Honda K24 tensioners collapse at 60k. Check oil changes – dirty oil kills tensioners 3x faster.

Can I drive with a noisy timing chain?

Not past 50 miles. That “rattle” means metal-on-metal contact. I towed a Camry last week where the chain ate through the cover – $2,400 repair vs $700 if caught early.

Why is timing chain replacement so expensive?

Labor dominates – 10+ hours for most V6 engines. Dealers charge $145/hr. Parts markup is 200% on tensioners. DIY the chain kit ($350) but pay a shop $400 for cam/crank alignment if unsure.

Conclusion: Your Engine’s Silent Guardian

Timing chains are the unsung heroes of modern engines – no maintenance, no reminders, just relentless precision. But when they whisper trouble, listen. I’ve seen too many good trucks scrapped because owners ignored that cold-start rattle. Replacement is complex but doable with the right specs and patience. For most DIYers, it’s a 14-hour project with $700 in costs – a fraction of dealer quotes. And remember: that oil change schedule? It’s your first defense against timing chain death. Keep it clean, keep it changed, and your chain will outlive the engine. As for Sarah’s F-150? We got her back on the road in 11 hours. She still brings me coffee every winter. Now go check that noise – your engine’s counting on you.

Mechanic’s Final Tip

Before replacing anything, remove the oil fill cap and listen with a mechanics stethoscope. A chain noise will be loudest at the timing cover – not the valve cover. If it’s silent there, you’re chasing the wrong ghost.