Quick Answer

To test a fuel pressure regulator, you’ll need a fuel pressure gauge and basic hand tools. The three main testing methods are: 1) Static pressure test (engine off), 2) Running pressure test (engine at idle), and 3) Vacuum test (checking pressure changes with vacuum applied). Normal fuel pressure typically ranges from 35-65 PSI depending on your vehicle, but always check your specific [fuel pressure specs](fuel-system-diagnosis) for accurate readings.

It was a sweltering Tuesday in July when a 2007 Honda Accord with 127,000 miles rolled into my bay. The customer, a frustrated teacher named Sarah, complained that her car was hesitating during acceleration and her fuel economy had dropped by nearly 30%. “My husband thinks it’s the fuel pump,” she said, wiping sweat from her brow, “but that’s going to cost a fortune, right?” I smiled, knowing that in my 15 years as an ASE-certified technician, I’ve seen these symptoms countless times, and often the culprit isn’t the expensive fuel pump but a much simpler component: the fuel pressure regulator. This $40-$120 part (depending on the vehicle) can cause all sorts of drivability issues when it fails, and learning how to test fuel pressure regulator function is a skill that can save you hundreds in unnecessary repairs.

Before we dive into the testing methods, it’s important to understand what a fuel pressure regulator (FPR) actually does. Simply put, it maintains consistent fuel pressure to the injectors, regardless of engine speed or load. Most modern vehicles use a vacuum-operated regulator that adjusts fuel pressure based on engine vacuum – higher vacuum (cruising) means lower fuel pressure, while lower vacuum (accelerating) means higher fuel pressure. When this component fails, you’ll experience poor performance, reduced fuel economy, and potentially even engine damage from running too rich or too lean.

Pro Tip: Before testing your FPR, make sure you have a basic understanding of [FPR problems, fuel pump testing, fuel system troubleshooting, vacuum leak testing](fuel-pressure-regulator-problems,how-to-test-fuel-pump,fuel-system-diagnosis,vacuum-leak-diagnosis). This knowledge will help you interpret your test results accurately.

Understanding Fuel Pressure Regulator Function

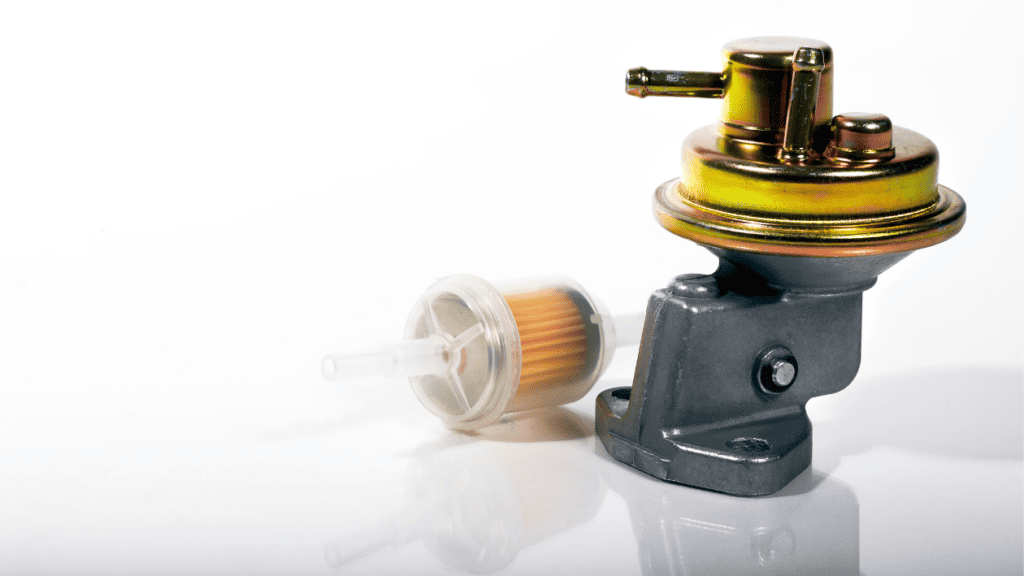

The fuel pressure regulator is essentially a spring-loaded diaphragm that balances against fuel pressure. On most vehicles, it’s located on the fuel rail, though some designs place it near the fuel tank. The regulator has a fuel inlet, a fuel return line, and a vacuum reference port. When engine vacuum is applied to the reference port, it helps the diaphragm open, allowing excess fuel to return to the tank. When vacuum drops (during acceleration), the diaphragm closes more, increasing fuel pressure to meet the engine’s demands.

There are three main types of fuel pressure regulators you might encounter:

- Vacuum-Operated Regulators: Most common in port fuel injection systems. These use engine vacuum to adjust fuel pressure.

- Returnless Systems: Found in many modern vehicles (post-2005). These don’t have a return line and typically use an electronic regulator integrated with the fuel pump module.

- Mechanical Regulators: Used in older vehicles with throttle body injection. These are less sophisticated and don’t use vacuum reference.

Understanding which type your vehicle has is crucial because testing methods differ slightly. For this guide, we’ll focus primarily on vacuum-operated regulators, as they’re the most common type you’ll encounter in DIY scenarios.

Essential Tools for FPR Testing

Before you begin testing your fuel pressure regulator, you’ll need to gather some tools. Having the right equipment not only makes the job easier but also ensures accurate readings and safety.

- Fuel Pressure Gauge Kit: This is non-negotiable. A good kit costs $40-$80 and includes various adapters for different fuel systems. I recommend the OTC 5609 or Actron CP7838 – both are quality kits I’ve used for years. Make sure it has a long enough hose (at least 3 feet) to keep the gauge away from hot engine components.

- Basic Hand Tools: You’ll need wrenches (8mm-17mm typically), screwdrivers, and pliers for disconnecting fuel lines.

- Hand Vacuum Pump: Essential for testing the vacuum reference port. The Mityvac MV8500 is the industry standard at around $60.

- Safety Equipment: Safety glasses, nitrile gloves, and a fire extinguisher rated for fuel fires (Class B).

- Shop Rags: Fuel will spill – it’s inevitable. Have plenty of absorbent rags ready.

- Fuel Line Disconnect Tools: Many modern vehicles use quick-connect fittings that require special tools. A universal kit costs about $20 and covers most applications.

Critical Safety Warning: Working with fuel systems is inherently dangerous. Fuel is highly flammable and its vapors can ignite with just a spark. Always work in a well-ventilated area, away from open flames or sparks. Never smoke while working on fuel systems. Disconnect the battery’s negative terminal before beginning any fuel system work to prevent accidental fuel pump activation.

Method 1: Static Fuel Pressure Test

The static fuel pressure test measures pressure with the engine off but the fuel system primed. This test helps determine if your fuel pump can generate adequate pressure and if the regulator is holding pressure when the engine is off.

Relieve Fuel System Pressure: Before connecting your gauge, you must relieve the system pressure. The easiest method is to remove the fuel pump fuse or relay, start the engine, and let it run until it stalls. Then crank the engine for 3-5 seconds to ensure all pressure is relieved. For most vehicles, the fuel pump fuse is located in the under-hood fuse box – consult your owner’s manual for the exact location.

Locate the Fuel Pressure Test Port: Most fuel-injected vehicles have a Schrader valve (similar to a tire valve) on the fuel rail for testing purposes. It typically has a black or blue plastic cap that says “Fuel Pressure.” If your vehicle doesn’t have one, you’ll need to connect the gauge inline by disconnecting a fuel line.

Connect the Fuel Pressure Gauge: Remove the cap from the test port and connect your gauge. The connection should be tight but don’t overtighten – you’re dealing with soft metal components that can easily strip.

Reconnect the Fuel Pump and Prime the System: Reinstall the fuel pump fuse or relay. Turn the key to the “ON” position (not start) for 2-3 seconds to prime the system. You should hear the fuel pump run briefly.

Record the Static Pressure: Read the pressure on your gauge. This is your static pressure reading. Compare it to your vehicle’s specifications (more on this later).

Check for Pressure Drop: Monitor the gauge for 5-10 minutes. The pressure should remain relatively stable. A drop of more than 5-10 PSI typically indicates a leaking injector, faulty check valve in the fuel pump, or a faulty regulator.

Technical Note: Static pressure for most vehicles should be 5-10 PSI higher than running pressure at idle. For example, if your vehicle specifies 45 PSI at idle, static pressure should be around 50-55 PSI. Always verify with your vehicle’s specific [fuel pressure specs](fuel-system-diagnosis).

Method 2: Running Fuel Pressure Test

This test measures fuel pressure with the engine running at various conditions. It’s the most comprehensive test for evaluating overall fuel pressure regulator performance.

Start the Engine: With the fuel pressure gauge still connected (from Method 1), start the engine and let it idle for 2-3 minutes to stabilize.

Record Idle Pressure: Note the fuel pressure at idle. This is your baseline reading. For most vehicles, this should be in the 35-45 PSI range, but it varies significantly between manufacturers.

Check Vacuum Reference: Locate the vacuum hose connected to the fuel pressure regulator. With the engine still idling, disconnect this hose. The fuel pressure should increase by approximately 5-10 PSI. This increase confirms that the vacuum reference is working correctly.

Test Under Load: With the help of an assistant, have them briefly rev the engine to 2,000-2,500 RPM while you watch the gauge. The pressure should increase slightly (by 2-5 PSI) and then stabilize. If pressure drops significantly during acceleration, the regulator may be failing or the fuel pump may be weak.

Pinch the Return Line: Caution: This step should be done briefly and carefully. Using appropriate fuel-line-safe pliers, gently pinch the fuel return line for 2-3 seconds while watching the gauge. The pressure should spike significantly (often doubling). If it doesn’t, either the regulator is stuck open or there’s a restriction in the fuel line before the regulator.

Shut Down and Observe: Turn off the engine and watch the pressure gauge for 5 minutes. As mentioned in Method 1, the pressure should hold relatively steady. A rapid pressure drop indicates a problem in the system.

Pro Tip: Take a picture of your gauge readings at each step with your phone. This creates a record you can reference later and helps you notice subtle changes in pressure that you might otherwise miss.

Method 3: Vacuum Test FPR

This specific test focuses on the vacuum-operated diaphragm inside the regulator. It’s particularly useful when you suspect the regulator diaphragm is torn or leaking.

Disconnect the Vacuum Line: With the engine off, locate and disconnect the vacuum hose from the fuel pressure regulator.

Inspect for Fuel: Look inside the disconnected vacuum hose and the regulator’s vacuum port. If you see any trace of fuel, the diaphragm is ruptured and the regulator must be replaced immediately. This is a common failure mode that can cause rough running, black smoke from the exhaust, and poor fuel economy.

Connect the Vacuum Pump: Attach your hand vacuum pump to the regulator’s vacuum port.

Apply Vacuum: Pump the vacuum pump to apply 15-20 inches of vacuum (Hg). The regulator should hold this vacuum without dropping for at least 30 seconds. If the vacuum drops, the diaphragm is leaking.

Observe Fuel Pressure Changes: If you still have your fuel pressure gauge connected, watch it as you apply vacuum. The fuel pressure should drop proportionally to the vacuum applied. This confirms that the regulator is responding correctly to vacuum changes.

Important: Never apply more than 20 inches of vacuum to the regulator. Excessive vacuum can damage the diaphragm. Also, never use compressed air to test the vacuum port – this can rupture the diaphragm and create a dangerous fuel leak.

Interpreting Your Test Results

Now that you’ve completed the tests, let’s interpret what the readings mean. I’ve created a simple diagnostic table based on thousands of vehicles I’ve worked on over the years:

| Symptom/Reading | Probable Cause | Next Steps |

|---|---|---|

| Static pressure too high (20+ PSI above spec) | Restricted return line or faulty regulator (stuck closed) | Check for kinked/blocked return line; replace regulator if line is clear |

| Static pressure too low (10+ PSI below spec) | Weak fuel pump or faulty regulator (stuck open) | Test fuel pump volume; replace regulator if pump tests good |

| Pressure drops rapidly after engine shutdown | Leaking injector, faulty check valve, or bad regulator | Perform injector balance test; replace regulator if injectors test good |

| No pressure change when vacuum applied/removed | Blocked vacuum reference or faulty regulator diaphragm | Check vacuum line for blockages; replace regulator if line is clear |

| Fuel present in vacuum line | Ruptured regulator diaphragm | Replace regulator immediately |

| Pressure drops significantly under acceleration | Weak fuel pump or clogged fuel filter | Test fuel pump volume; replace filter if needed |

Technical Note: Fuel pressure specifications vary widely between manufacturers. For example, a 2005 Ford F-150 with the 4.6L V8 should show 35-45 PSI at idle, while a 2005 Toyota Camry with the 2.4L engine should show 55-61 PSI. Always verify the exact specifications for your vehicle before condemning any parts.

Vehicle-Specific Considerations

While the testing methods above work for most vehicles, there are some notable exceptions and variations worth mentioning:

Returnless Fuel Systems

Many vehicles manufactured after 2005 use returnless fuel systems. These systems don’t have a traditional fuel pressure regulator on the fuel rail. Instead, they use either:

- Electronic Regulators: Controlled by the PCM (Powertrain Control Module) based on sensor inputs

- Integrated Regulators: Built into the fuel pump module in the tank

For these systems, testing is slightly different. You’ll still connect a fuel pressure gauge to the test port, but you won’t find a vacuum reference to test. Instead, you’ll compare actual pressure to specified pressure at idle and under various conditions. Some of these systems require a scan tool to command the fuel pump on at different speeds for comprehensive testing.

Direct Injection Systems

Direct injection vehicles (like many modern Audis, VWs, and BMWs) have two fuel systems: a low-pressure system (typically 50-70 PSI) and a high-pressure system (up to 2,000 PSI). The low-pressure system usually has a traditional regulator that can be tested with the methods above. The high-pressure system requires special tools and should only be tested by trained technicians due to the extreme pressures involved.

Diesel Engines

Diesel fuel systems operate at much higher pressures (often 1,500-30,000 PSI) and require specialized testing equipment. The methods described in this article are not suitable for diesel engines.

Common Fuel Pressure Regulator Problems

In my 15+ years as a technician, I’ve seen fuel pressure regulators fail in several predictable ways. Understanding these failure modes can help you diagnose problems more accurately:

Diaphragm Rupture

This is the most common failure mode, especially on vehicles with 100,000+ miles. When the diaphragm tears, fuel can be drawn directly into the intake manifold through the vacuum line. Symptoms include:

- Black smoke from the exhaust

- Strong fuel smell from the engine bay

- Poor fuel economy (often 20-30% worse than normal)

- Rough idle and stalling

- Fouled spark plugs

I once had a 2002 Chevy Silverado with a 5.3L V8 that was getting 8 MPG instead of its normal 16. The customer had already replaced plugs, wires, and even the MAF sensor. A quick check of the regulator vacuum line revealed it was full of fuel – a classic ruptured diaphragm. A $45 regulator and new plugs solved the problem instantly.

Stuck Open/Closed

Regulators can also fail by sticking in either the open or closed position:

- Stuck Open: Causes low fuel pressure, leading to hesitation, poor acceleration, and potential engine damage from running too lean.

- Stuck Closed: Causes high fuel pressure, leading to rich running, fouled plugs, and potential damage to fuel injectors.

Spring Fatigue

Over time, the internal spring can weaken, causing the regulator to maintain incorrect pressure. This failure is gradual and often mistaken for other issues like a weak fuel pump or clogged fuel filter.

Replacing a Fuel Pressure Regulator

If your tests confirm a faulty regulator, replacement is usually straightforward. Here’s what you need to know:

Cost Analysis

| Repair Option | Parts Cost | Labor Cost | Total Cost |

|---|---|---|---|

| DIY Replacement | $40-$120 (depending on vehicle) | $0 (your time) | $40-$120 |

| Independent Shop | $40-$120 | $80-$150 | $120-$270 |

| Dealership | $60-$180 (OEM parts) | $120-$250 | $180-$430 |

Money-Saving Tip: For most domestic vehicles, aftermarket regulators from brands like Standard Motor Products or ACDelco are perfectly fine and often come with a lifetime warranty. For European vehicles, I usually recommend OEM parts as aftermarket options can be hit-or-miss in terms of quality.

Replacement Procedure

While exact procedures vary by vehicle, here’s the general process:

Relieve Fuel Pressure: As described earlier, remove the fuel pump fuse and run the engine until it stalls.

Disconnect Fuel Lines: Carefully disconnect the fuel lines from the regulator. Have rags ready to catch any drips. For quick-connect fittings, use the appropriate disconnect tool to avoid damaging the fuel lines.

Remove Vacuum Line: Disconnect the vacuum reference hose.

Unbolt the Regulator: Most regulators are attached with 2-3 small bolts. Note the orientation before removal.

Install New Regulator: Install the new regulator with a new O-ring or gasket (never reuse the old one). Tighten bolts to manufacturer specifications – typically 8-12 ft-lbs. Don’t overtighten!

Reconnect Everything: Reattach fuel lines and vacuum hose. Reinstall the fuel pump fuse.

Test for Leaks: Turn the key to “ON” for 3 seconds to pressurize the system, then OFF. Repeat this 2-3 times while carefully checking for any fuel leaks. Start the engine and verify proper operation.

Critical Warning: After replacing a fuel pressure regulator, always perform a fuel pressure test to verify the new part is functioning correctly. I’ve seen brand-new regulators fail right out of the box – it’s rare but happens enough that verification is essential.

Frequently Asked Questions

Conclusion

Learning how to test fuel pressure regulator function is a valuable skill for any DIY mechanic or automotive enthusiast. With just a $40-$80 fuel pressure gauge and some basic knowledge, you can diagnose what might otherwise be an expensive and frustrating problem. The three testing methods I’ve outlined – static pressure test, running pressure test, and vacuum test – will help you identify regulator issues with confidence.

Remember that fuel system work requires attention to safety and detail. Always relieve system pressure before disconnecting lines, work in a well-ventilated area, and have a fire extinguisher nearby. When in doubt, consult a professional – fuel leaks are nothing to take lightly.

From my perspective as a technician, I’ve seen countless customers save hundreds of dollars by learning to test their own fuel pressure regulators. The 2007 Honda Accord I mentioned at the beginning? A simple pressure test revealed a faulty regulator that was holding at 70 PSI instead of the specified 48 PSI. A $65 part and 30 minutes of work solved her hesitation and fuel economy issues, saving her the $600+ she was quoted for a new fuel pump at another shop.

That’s the beauty of understanding your vehicle’s systems – knowledge truly is power when it comes to automotive repair. With the methods outlined in this guide, you’re now equipped to diagnose fuel pressure regulator issues like a pro.