Quick Answer

Proper carburetor adjustment involves setting the idle speed, adjusting the air-fuel mixture screws, and tuning the accelerator pump. For most vehicles, start with a 1.5-2 turn out on the mixture screws, then fine-tune while listening to engine response and checking spark plug color. Always perform adjustments with the engine at operating temperature.

A Cold Morning, A Classic Camaro, and a Carburetor Nightmare

It was 7:15 AM on a crisp Tuesday in November when Mark rolled into my shop in his ’68 Camaro. The temperature was hovering around 38°F, and you could see your breath in the air. Mark had just bought the classic beauty at an auction the previous weekend, and his excitement was palpable—until he tried to start it that morning.

“She just won’t stay running,” he said, frustration evident in his voice. “I pump the gas, she fires up, then dies immediately. If I keep feathering the throttle, I can keep her going, but the second I let off, she quits.”

I’ve seen this scenario hundreds of times in my 15 years as an ASE-certified technician. After a quick diagnostic, I identified the culprit: the carburetor was way out of tune. The previous owner had apparently tried to “tune” it himself, making adjustments without understanding the relationship between the idle circuit, main circuit, and choke system.

Two hours later, with proper carburetor adjustment completed, Mark’s Camaro was purring like a kitten—even in the cold morning air. His relief was obvious, and it reminded me why I love what I do: solving problems and helping people enjoy their vehicles.

This experience is exactly why I’m writing this comprehensive guide to carburetor adjustment. Whether you’re working on a classic car, a vintage motorcycle, or any carbureted engine, understanding proper carb tuning can save you headaches and money.

Understanding Carburetor Basics

Before diving into carburetor adjustment, let’s cover what a carburetor actually does. In simple terms, a carburetor mixes air and fuel in the right proportions for combustion. It’s a mechanical device that uses the Venturi effect to draw fuel into the airstream entering the engine.

Modern fuel injection systems have largely replaced carburetors, but millions of vehicles still rely on them, especially:

- Classic cars and trucks (pre-1990 for most models)

- Many motorcycles (especially cruisers and off-road bikes)

- Small engines (lawnmowers, generators, etc.)

- Performance applications where carburetors are preferred for their simplicity and tuning potential

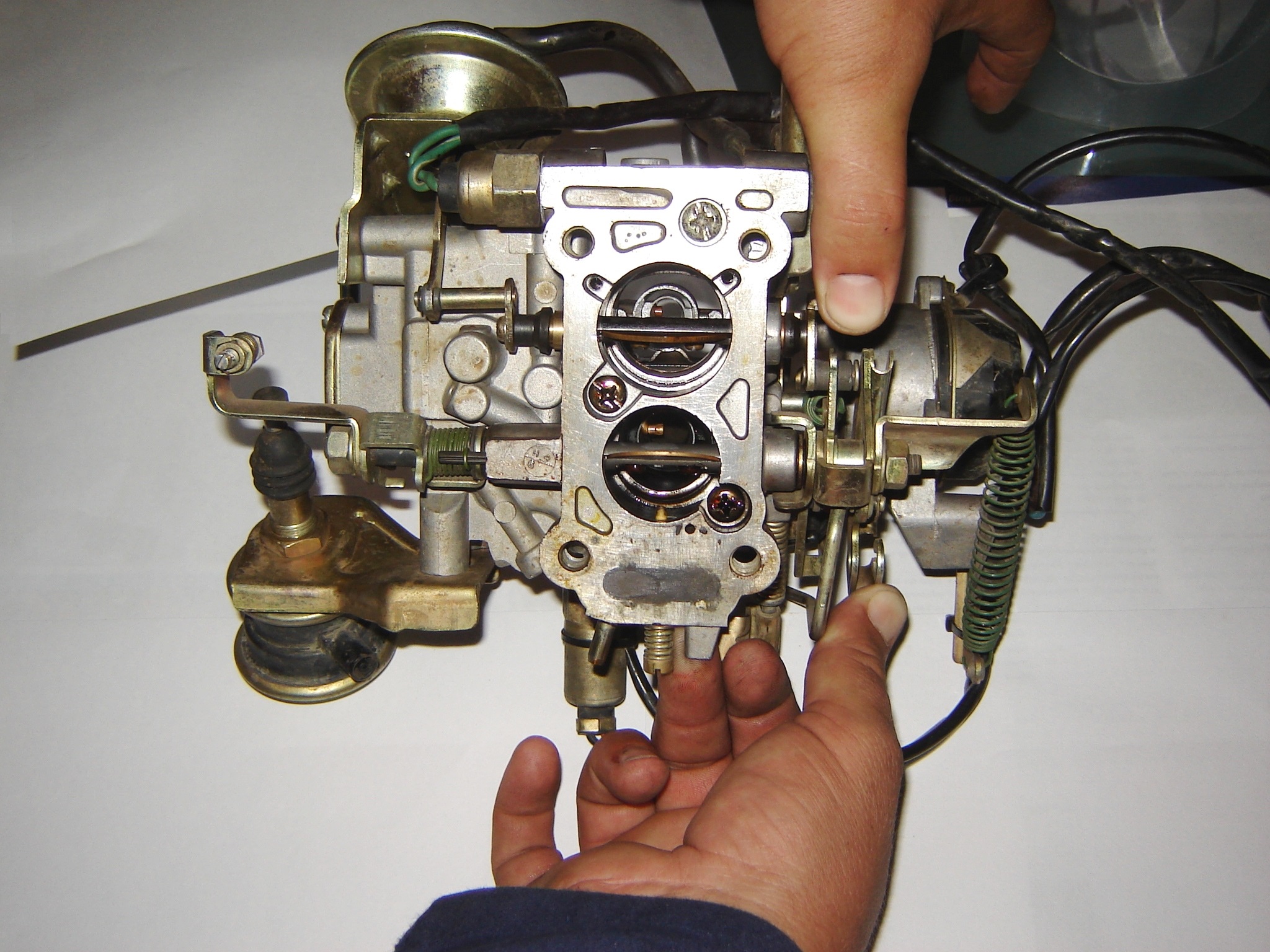

Key Carburetor Components

For effective carburetor adjustment, you need to understand these critical components:

- Float Bowl: Holds the fuel reservoir and maintains a consistent fuel level via the float and needle valve

- Venturi: The narrow passage where air speed increases, creating a pressure drop that draws fuel

- Throttle Plate: Controls airflow into the engine, regulated by the throttle pedal

- Idle Circuit: Handles fuel delivery at low engine speeds (idle)

- Main Circuit: Manages fuel delivery at mid-to-high engine speeds

- Power Circuit: Provides extra fuel under heavy load or acceleration

- Choke System: Enriches the fuel mixture for cold starts

- Accelerator Pump: Squirts extra fuel when the throttle is suddenly opened

When Do You Need Carburetor Adjustment?

Several symptoms indicate your carburetor needs adjustment:

- Engine stumbles or hesitates during acceleration

- Poor fuel economy

- Black smoke from the exhaust (rich mixture)

- Engine backfiring through the carburetor (lean mixture)

- Difficulty starting, especially when cold

- Irregular or unstable idle

- Engine stalls when coming to a stop

- Poor performance at high altitude

Pro Tip: Before making any carburetor adjustments, ensure your engine is in good mechanical condition. Check for vacuum leaks, verify ignition timing, and confirm your spark plugs and wires are healthy. A properly tuned carburetor can’t compensate for underlying mechanical issues.

Tools and Materials for Carburetor Adjustment

Having the right tools makes carburetor adjustment much easier and more precise. Here’s what you’ll need:

- Screwdriver set with both flathead and Phillips heads (including small jewelers’ screwdrivers for mixture screws)

- Carburetor adjustment tool (for some carburetors with special mixture screws)

- Tachometer (for accurate idle speed setting)

- Vacuum gauge (for balancing multiple carburetors and checking engine health)

- Feeler gauges (for checking choke plate gap)

- Carburetor cleaner (for cleaning during the process)

- Shop rags or paper towels

- Safety glasses and gloves

- Spark plug socket and ratchet (for checking plug color)

- Fuel line clamp (to prevent fuel spillage)

Tool Budget: A basic carburetor adjustment tool set will run you $30-60. A quality tachometer costs $40-80, and a vacuum gauge is $25-50. If you’re doing this work yourself, these tools will pay for themselves after just one use compared to shop rates.

Preparing for Carburetor Adjustment

Before you begin making adjustments, proper preparation is essential:

Start with a clean carburetor: If your carburetor is dirty or has varnish buildup, adjustments won’t be effective. Consider performing a [carburetor cleaning](carburetor-cleaning-guide) first, or in severe cases, a complete [carburetor rebuild](carburetor-rebuild-kit-guide).

Warm up the engine: All carburetor adjustments should be made with the engine at normal operating temperature. Drive the vehicle for 10-15 minutes or let it idle until the temperature gauge reaches the normal range.

Set the choke: Make sure the choke is fully open after the engine is warm. If the choke remains partially closed, it will affect all your adjustments.

Turn off accessories: Switch off A/C, lights, and other electrical loads that might affect idle speed.

Check for vacuum leaks: Spray carburetor cleaner around the carburetor base, intake manifold gaskets, and vacuum hoses while the engine is running. If the idle speed changes when you spray in a particular area, you have a vacuum leak that needs to be fixed before proceeding.

Safety Warning: Working with carburetor cleaner near a running engine is hazardous due to flammability. Keep a fire extinguisher nearby, work in a well-ventilated area, and avoid open flames or sparks. Wear safety glasses to protect your eyes from spray back.

Carburetor Adjustment: Step-by-Step Guide

Now that you’re prepared, let’s dive into the actual carburetor adjustment process. While carburetors vary by manufacturer, these general principles apply to most designs.

Step 1: Setting the Idle Speed

The first adjustment is setting the base idle speed. This is typically done with the idle speed screw, which controls the throttle plate position at idle.

Locate the idle speed screw. It’s usually a large screw that contacts the throttle linkage.

Start the engine and let it reach operating temperature.

Connect your tachometer according to the manufacturer’s instructions.

Turn the idle speed screw clockwise to increase idle speed or counterclockwise to decrease it.

Set the idle to the manufacturer’s specification (typically 600-900 RPM for most vehicles, but check your service manual).

Note: Don’t set the idle too high to mask other problems. An excessively high idle can cause transmission engagement issues, excessive wear, and poor fuel economy.

Step 2: Adjusting the Air-Fuel Mixture

This is the most critical part of carburetor adjustment. The air-fuel mixture screws control the ratio of fuel to air at idle and low speeds.

Locate the mixture screws. Most carburetors have one or two mixture screws, typically located on the base or lower front of the carburetor.

Some carburetors have “limiting caps” that prevent full adjustment. These may need to be carefully removed with pliers.

Gently turn each mixture screw clockwise until it lightly seats. Do not overtighten as this can damage the screw and seat.

Turn each screw counterclockwise the specified number of turns. For most carburetors, this is 1.5 to 2.5 turns out from fully seated.

With the engine running, slowly turn one mixture screw in either direction while listening to the engine sound.

Find the point where the engine runs smoothest and the RPM is highest. This is typically the optimal setting.

Repeat for the other mixture screw if applicable.

Readjust the idle speed screw if necessary to bring the RPM back to specification.

Pro Tip: The “highest smooth RPM” method works well, but for precise tuning, use a vacuum gauge. Adjust each mixture screw to achieve the highest, steady vacuum reading. This method is more accurate and less subjective than just listening to the engine.

Step 3: Tuning the Accelerator Pump

The accelerator pump provides extra fuel when you first open the throttle, preventing hesitation. If your engine stumbles when you press the accelerator, the pump may need adjustment.

With the engine off, look down the carburetor throat while working the throttle.

You should see a stream of fuel shoot from the accelerator pump nozzle each time you open the throttle.

If no fuel squirts, or if the stream is weak, check the pump linkage and adjust according to your carburetor’s specifications.

Many carburetors have multiple holes for the pump linkage. Moving the linkage to a different hole changes the timing and volume of the pump shot.

Test drive the vehicle to check for hesitation off the line. Adjust as needed.

Step 4: Adjusting the Choke

Proper choke operation is crucial for cold starts. Here’s how to adjust it:

With the engine cold, remove the air cleaner to observe the choke plate.

The choke plate should be fully closed when cold.

Start the engine and watch the choke plate. It should begin to open gradually as the engine warms.

After 5-10 minutes of running, the choke should be fully open.

If the choke opens too quickly or too slowly, adjust the choke spring tension or the choke unloader mechanism according to your carburetor’s specifications.

Advanced Carburetor Tuning Techniques

For those looking to optimize performance beyond basic adjustments, these advanced techniques can help you fine-tune your carburetor for specific applications.

Altitude Tuning

Air density decreases at higher altitudes, requiring leaner fuel mixtures. If you live or drive at significantly different altitudes, you may need to adjust your carburetor accordingly:

- For every 1,000 feet above sea level, reduce jet size by approximately 2-3%

- At high altitude, turn mixture screws in (leaner) by about 1/8 turn per 2,000 feet

- Consider an altitude compensator if you frequently drive between varying elevations

Performance Tuning

For those seeking maximum [engine performance tuning](engine-performance-tuning), carburetor modifications can provide significant gains:

- Increasing jet size can provide more fuel for high-RPM operation

- Changing the power valve spring rate can adjust when the power circuit engages

- Modifying the accelerator pump cam profile can tailor throttle response

- For [classic car performance](classic-car-performance) applications, consider a carburetor with larger venturis to increase airflow

Caution: Performance tuning requires careful monitoring of spark plug color and engine temperatures. An overly lean mixture can cause detonation and severe engine damage. If you’re not experienced with performance tuning, consider consulting a professional or investing in a wideband oxygen sensor system for accurate air-fuel ratio monitoring.

Troubleshooting Common Carburetor Issues

Even with proper adjustment, issues can arise. Here are common problems and their solutions:

Engine Stalls at Idle

Symptoms: Engine runs fine when driving but dies when coming to a stop.

Solutions:

- Check and adjust idle speed

- Adjust mixture screws (often too lean)

- Check for vacuum leaks

- Verify the idle solenoid (if equipped) is functioning

- Clean the idle passages in the carburetor

Poor Fuel Economy

Symptoms: Vehicle uses more fuel than usual, black smoke from exhaust.

Solutions:

- Adjust mixture screws (likely too rich)

- Check float level (may be too high)

- Verify choke is fully opening when warm

- Check for stuck open power valve

- Consider smaller jets for fuel efficiency

Engine Hesitation on Acceleration

Symptoms: Engine stumbles or bogs when you press the accelerator.

Solutions:

- Adjust accelerator pump linkage or pump shot volume

- Check for weak accelerator pump spring

- Verify accelerator pump check valve is functioning

- Clean clogged pump nozzle or passages

- Consider larger pump shooter nozzle

Hard Starting When Cold

Symptoms: Engine requires extensive cranking to start when cold.

Solutions:

- Adjust choke for proper closing when cold

- Check choke pull-off for proper operation

- Verify choke spring tension is appropriate for your climate

- Check fuel level in float bowl (may be draining overnight)

- Consider an electric fuel pump for better priming

Cost Analysis: DIY vs. Professional Carburetor Adjustment

Understanding the costs involved can help you decide whether to tackle carburetor adjustment yourself or seek professional help.

| Cost Factor | DIY Approach | Professional Service |

|---|---|---|

| Basic Tools | $50-150 (one-time purchase) | $0 (included in service) |

| Carburetor Cleaner | $8-15 | $0 (included in service) |

| Basic Adjustment | $0 (just your time) | $100-200 |

| Carburetor Rebuild | $50-150 (parts only) | $300-500 (parts + labor) |

| Performance Tuning | $100-300 (jets + parts) | $400-800 (specialty service) |

Time Investment: A basic carburetor adjustment typically takes 30-60 minutes for an experienced DIYer. A complete rebuild might require 2-4 hours. Professional services usually quote 1-2 hours for basic adjustment and 3-5 hours for a rebuild.

Money-Saving Tip: Many shops charge a minimum of 1 hour labor even for simple adjustments. Learning to do basic carburetor adjustment yourself can save you $100+ per visit. The skills you gain will pay for themselves after just one or two adjustments.

Frequently Asked Questions About Carburetor Adjustment

Under normal conditions, a properly tuned carburetor should maintain its adjustment for 6,000-12,000 miles. However, changes in fuel quality, altitude, or engine wear may require more frequent adjustments. I recommend checking your carburetor settings at least once a year or whenever you notice performance issues.

Absolutely. A properly tuned carburetor can improve fuel economy by 10-15% compared to one that’s running rich. The key is finding the right balance between performance and efficiency. Slightly leaner mixtures typically yield better fuel economy, but going too lean can cause engine damage and poor drivability.

While basic adjustments can be made with simple screwdrivers, having the right tools makes the job easier and more precise. A tachometer is essential for setting idle speed correctly, and a vacuum gauge helps optimize the air-fuel mixture. Some carburetors also require special adjustment tools for the mixture screws, which are often tamper-resistant.

Air density changes with temperature, affecting the air-fuel ratio. In hot weather, air is less dense, effectively making the mixture richer. In cold weather, the denser air makes the mixture leaner. This is why carburetors have choke systems for cold starts and why some performance enthusiasts adjust their carburetors seasonally.

Basic carburetor adjustment is moderately challenging for beginners but definitely achievable with patience and the right guidance. The key is understanding what each adjustment does and making small changes methodically. Start with simple adjustments like idle speed before tackling the more complex mixture settings. Always work in small increments and document your changes.

Yes, an improperly adjusted carburetor can cause serious engine damage. A mixture that’s too lean can cause detonation, overheating, and burned pistons. A mixture that’s too rich can lead to carbon buildup, washed cylinder walls (reducing lubrication), and catalytic converter failure. This is why proper carburetor adjustment is crucial for engine longevity.

Conclusion: Mastering the Art of Carburetor Adjustment

Carburetor adjustment is both a science and an art. While the principles are straightforward, achieving the perfect balance of performance, efficiency, and drivability requires patience, attention to detail, and a willingness to experiment.

For DIY mechanics, carburetor adjustment is a moderately challenging skill that’s well worth developing. The satisfaction of hearing your engine run perfectly after your own adjustments is immensely rewarding, and the money you’ll save over professional services adds up quickly.

Remember that carburetor adjustment is just one aspect of [engine performance tuning](engine-performance-tuning). For optimal results, ensure your entire ignition and fuel systems are in good condition. Regular maintenance, including periodic [carburetor cleaning](carburetor-cleaning-guide), will keep your vehicle running smoothly for years to come.

After 15 years in the shop, I can tell you that understanding how to tune a carburetor is a skill that serves any automotive enthusiast well. Whether you’re maintaining a daily driver or optimizing a [classic car performance](classic-car-performance) machine, the principles remain the same. Start with the basics, be methodical in your approach, and don’t be afraid to experiment within safe limits.

Your vehicle will thank you with better performance, improved fuel economy, and the unmistakable sound of an engine running exactly as it should.