Quick Answer: Fuel injector cleaning restores engine performance by removing carbon deposits from the pintle and nozzle. For minor maintenance, Polyetheramine (PEA) additives work well. for moderate clogging, a pressurized rail injector cleaning kit is the industry standard. However, for severely dirty fuel injectors causing misfires, off-car ultrasonic cleaning or replacement is the only guaranteed fix.

The “Phantom Misfire” on a Rainy Tuesday

It was a soaking wet Tuesday in November when a customer towed in a 2014 Ford F-150 with the 5.0L Coyote V8. He looked exhausted. He’d spent the entire weekend firing the “parts cannon” at his truck. He had replaced the spark plugs, ignition coils, and even the MAF sensor because of a persistent rough idle and a stumble under load.

“It’s still doing it,” he told me, wiping grease off his forehead. “I’ve spent $600 in parts, and it runs exactly the same.”

I pulled the truck into the bay, hooked up my scan tool, and looked at the fuel trims. The Long Term Fuel Trim (LTFT) on Bank 1 was sitting at +22%. The computer was screaming for more fuel, but the engine wasn’t getting it. I didn’t need to replace a single sensor. I pulled the fuel rail, and sure enough, two injectors were practically dribbling fuel rather than spraying a fine mist. A proper fuel injector service saved the truck, but the customer could have saved $600 if he knew what to look for first.

Today, I’m going to walk you through exactly how to diagnose, clean, and maintain your injectors so you don’t end up like that guy.

Why Injectors Fail (and Why Additives Aren’t Enough)

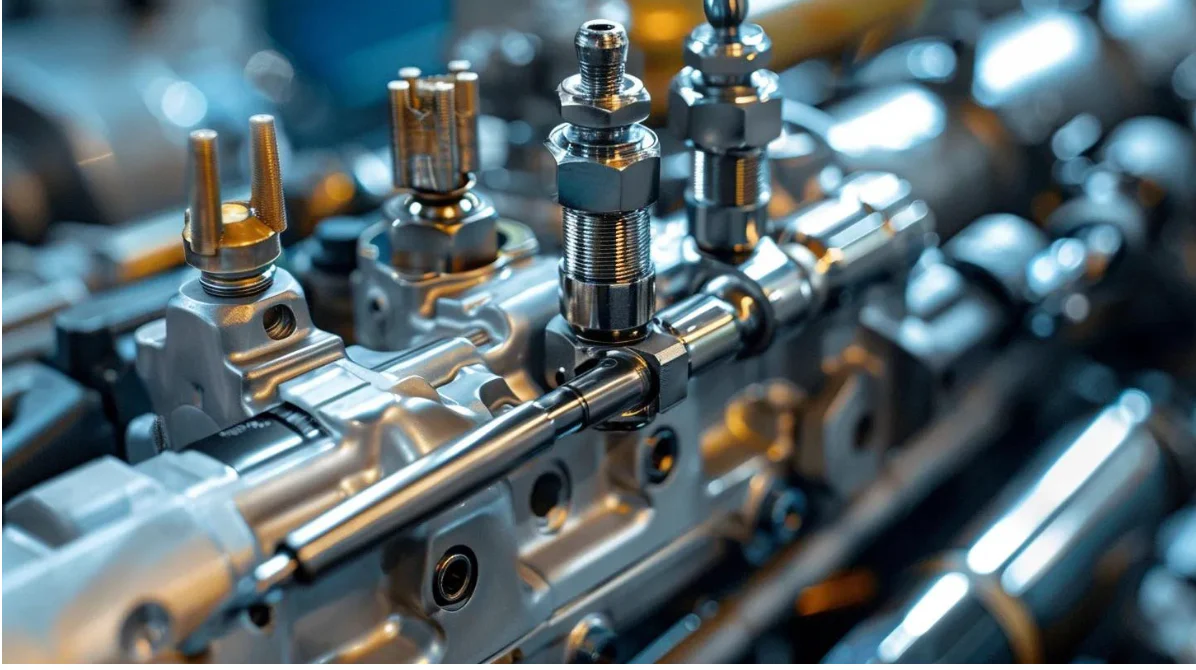

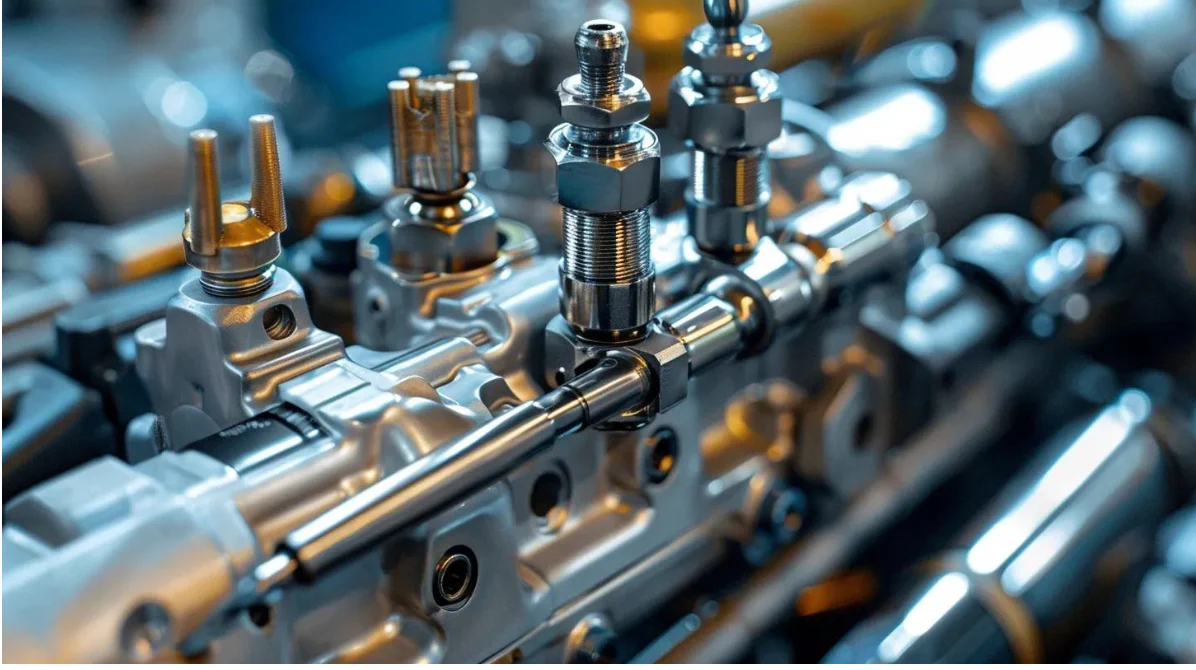

Your fuel injectors are precision solenoids. They open and close thousands of times per minute. On a standard port-injection engine, they operate around 40–60 PSI. On modern GDI (Gasoline Direct Injection) engines, we are talking about pressures upwards of 2,000 PSI.

Over time, heat soak turns residual fuel into hard carbon varnish on the pintle (the tiny needle inside the injector) and the nozzle cap. This disrupts the spray pattern. Instead of a fine mist that atomizes perfectly for combustion, you get a stream. Think of putting your thumb over a garden hose: if you do it right, you get a wide spray. If you mess it up, you just get a heavy stream that hits the dirt.

Symptoms of Clogged Injectors

Before you go buying tools, verify the symptoms. Dirty fuel injectors usually present as:

- Rough Idle: The engine shakes at stoplights because cylinders aren’t getting equal fuel. (See our guide on rough idle solutions).

- Hesitation/Stumble: When you mash the gas, there’s a delay. This is often confused with acceleration problems related to ignition.

- Lean Codes (P0171/P0174): This is the big one. If your oxygen sensors see too much air and not enough fuel, the Check Engine Light pops on.

- Failed Emissions: High Hydrocarbons (HC) and Carbon Monoxide (CO).

The Three Tiers of Cleaning

Not all cleaning methods are created equal. Here is the hierarchy of effectiveness based on my 15 years in the shop.

Level 1: Pour-in Tank Additives (Maintenance Only)

Effectiveness: Low to Moderate

Best for: Prevention and very mild deposits.

The Reality: Most cheap bottles at the gas station are kerosene and naphtha—basically paint thinners. They won’t fix a dead injector. You need chemistry containing PEA (Polyetheramine). This is the only chemical strong enough to survive combustion temperatures and clean the deposits.

- Top Pick: Chevron Techron Concentrate Plus or Red Line SI-1.

- Usage: Use one bottle every oil change (5,000 miles).

Level 2: On-Car Pressurized Cleaning (The DIY Sweet Spot)

Effectiveness: High

Best for: Correcting rough idle and restoring MPG.

The Reality: This is what we call a “flush” at the dealership. We disable the fuel pump and run the engine off a canister of pure, concentrated cleaner pressurized by shop air. The engine runs on this solvent for 10-15 minutes.

Level 3: Off-Car Ultrasonic Cleaning (The Nuclear Option)

Effectiveness: 100%

Best for: Restoring old cars, high-performance builds, or saving expensive injectors.

The Reality: This involves removing the injectors and putting them in a professional cleaning machine. They are pulsed electronically while submerged in a heated ultrasonic bath. We also replace the micro-filters and O-rings. If ultrasonic cleaning doesn’t save them, they are trash.

DIY Guide: The Pressurized Rail Method

If you are comfortable working with tools, the On-Car Pressurized method is the most effective DIY route. Here is how to do it safely.

Tools & Materials Needed

- Injector Cleaning Kit: You need a canister style tool. The OTC 7448A Fuel Injection Cleaner is the industry standard. (Cost: ~$150).

- Cleaning Solvent: OTC 7000A Pro Inject-R Kleen or equivalent professional solvent.

- Air Compressor: Small pancake compressor is fine.

- Fuel Line Disconnect Tools: Lisle 37000 set is a lifesaver for Fords and GMs.

- Safety Glasses & Nitrile Gloves: Mandatory.

CRITICAL SAFETY WARNING: You are working with highly flammable chemicals under pressure.

- Perform this outdoors or in a well-ventilated bay.

- Keep a Class B fire extinguisher within arm’s reach.

- Depressurize the system: Pull the fuel pump fuse and crank the engine until it stalls BEFORE disconnecting any lines. Fuel spray on a hot exhaust manifold = fire.

Isolate the Fuel System

Locate your fuel pump fuse or relay and pull it. Start the car and let it run until it dies. This removes the pressure from the fuel rail. Turn the ignition off.

Disable Fuel Return (If Applicable)

On older vehicles (pre-2004 usually) with a return-style system, you must block the return line or loop it. If you don’t, the cleaning solvent will just flow right back into your gas tank. Use a pinching plier on the soft rubber return line, or loop the feed/return at the tank if accessible. Note: Most modern cars are “returnless” and skip this step.

Setup the Canister

Fill your cleaning canister with the solvent. Hook the canister to your air compressor. Set the regulator on the canister to match your vehicle’s specific fuel pressure.

Rule of Thumb Pressures:

* Port Injection (Most Asian/Domestic): 45–55 PSI

* TBI (Older GM/Dodge): 12–15 PSI

* Euro (BMW/VW): Check manual, usually 3.5–4.0 Bar (50–58 PSI)

Do not guess here. Too much pressure can rupture the diaphragm in the fuel rail damper.

Connect and Run

Connect the canister output hose to the fuel rail Schrader valve (test port). If you don’t have a Schrader valve, you will need to disconnect the main fuel line and use an adapter. Open the valve on the canister. Check for leaks immediately.

Start the engine. It is now running solely on the cleaning solvent. It might idle slightly rough—that’s normal. Let it run until the engine stalls (when the canister is empty). This usually takes 10–15 minutes.

Reassembly

Close the canister valve. Depressurize the canister slowly. Disconnect from the rail. Reinstall your fuel pump fuse. Cycle the key to the “ON” position (do not start) 3 times to prime the pump. Start the car and check for leaks again.

Technical Data & Troubleshooting

Sometimes cleaning isn’t the answer. You need to know when an injector is electrically dead. You can check this with a multimeter.

Ohm Testing Injectors

A good injector coil generally has a specific resistance. If the coil is open (infinite resistance) or shorted (zero resistance), no amount of cleaning will fix it.

$$V = I \times R$$

Typical Specifications (Port Injection):

- High Impedance (Saturated): 12 to 16 Ohms (Most common passenger cars)

- Low Impedance (Peak & Hold): 2 to 4 Ohms (Older performance cars, some turbos)

Troubleshooting Matrix:

| Symptom | Check First | Solution |

|---|---|---|

| Single Cylinder Misfire | Swap ignition coil to another cylinder. Does misfire move? | If misfire stays, check injector resistance and use a “Noid Light” to check for pulse. |

| Hard Start (Hot) | Fuel Pressure Regulator & Injector Leak Down | Injectors may be leaking (dripping) after shutoff, flooding the engine. Needs replacement. |

| Smell of Raw Gas | External O-Rings | The O-rings dry rot. Do not drive. Replace O-rings immediately. |

Cost Analysis: Is DIY Worth It?

Let’s break down the math. I’m assuming you’re driving a standard V6 sedan.

Option A: The Shop (Professional)

- Service: On-car rail flush

- Labor: 1.5 Hours @ $150/hr = $225

- Parts/Fluid: $45

- Total: $270 – $350

Option B: DIY (Canister Method)

- OTC 7448A Tool: $150 (One time buy)

- Solvent: $15

- Total (First Time): $165

- Total (Next Time): $15

Option C: Replacement (The “I give up” Method)

- Parts: 6 OEM Injectors @ $80/each = $480

- Labor: $300

- Total: $780+

FAQ: Questions I Hear at the Counter

How often should I clean my fuel injectors?

For pour-in additives, I recommend every oil change (5,000 miles). For the pressurized rail cleaning method described above, do it every 30,000 miles. This aligns with most major service intervals and keeps carbon buildup on the valves (especially on GDI engines) to a minimum.

Can I clean GDI (Direct Injection) injectors myself?

You can use the rail method on GDI engines, but it is less effective at cleaning the intake valves because the fuel doesn’t wash over them. For GDI injectors that are truly clogged, on-car cleaning rarely works well because the pressures are so high (2,000+ PSI). These usually require removal and professional ultrasonic cleaning.

Will cleaning fix a leaking injector?

No. If an injector is leaking (dripping fuel when closed), it means the internal spring is weak or the seat is physically damaged. Cleaning might actually make it leak worse by removing the carbon that was sealing the gap. A leaking injector must be replaced to prevent cylinder wash-down.

Can I just use Seafoam?

Seafoam is a solvent, but it’s old technology (mostly pale oil and naphtha). It creates a lot of smoke, which looks cool, but for modern injectors with microscopic tolerances, you want a cleaner with a high concentration of PEA (Polyetheramine). It’s safer for your catalytic converters and O2 sensors.

The Bottom Line

Fuel injector cleaning isn’t snake oil, but it isn’t a miracle cure for a broken car either. It is maintenance. If you catch it early, a $15 can of PEA cleaner is all you need. If you let it go until the engine is shaking the fillings out of your teeth, you’re going to need the canister kit or a new set of injectors.

I’ve seen too many good engines ruined by lean conditions caused by clogged injectors. Don’t ignore a rough idle. Grab a canister kit, follow the safety steps, and blow that carbon out. Your throttle response will thank you.

Now, go check your tire pressure while you’re at it.