Quick Answer: An engine compression test measures the pressure in each cylinder to diagnose issues like worn piston rings, leaking valves, or a blown head gasket. A healthy engine should have compression between 125-175 PSI per cylinder, with no more than 10% variation between cylinders.

The Day I Diagnosed a “Dead” Engine with a $40 Tool

It was a sweltering July afternoon in my shop, the kind of heat that makes the asphalt sticky and turns your coveralls into a sauna. A tow truck had just dropped off a 2008 Toyota Camry with 180,000 miles on the odometer. The owner, a college student named Jake, looked defeated. “The dealer said I need a new engine—$4,500. But I can’t afford that. Can you at least tell me if it’s really dead?”

I grabbed my compression tester—a simple $40 tool I’d used a thousand times—and told Jake to give me 30 minutes. What I found wasn’t a dead engine, but a simple case of worn valve stem seals and a single bad spark plug. Two hours and $120 in parts later, that Camry purred like a kitten. Jake drove away with his wallet intact, and I got another reminder: 90% of “dead” engines just need someone to listen to what they’re really saying.

That’s the power of a compression test. It’s not just a diagnostic tool—it’s a crystal ball for your engine’s health. And the best part? Any weekend mechanic can do it with basic tools and a little patience. Here’s how to perform a compression test like a pro, interpret the results, and avoid getting scammed by a lazy diagnosis.

What Is an Engine Compression Test?

An engine compression test measures the maximum pressure each cylinder can generate during the combustion stroke. Think of it like checking the “pulse” of your engine. Healthy cylinders should all produce similar pressure readings. If one or more cylinders are weak, you’ve got a problem that needs diagnosing.

This test helps identify:

- Worn piston rings

- Leaking or burnt valves

- Blown head gaskets

- Cracked cylinder heads

- Holes in pistons

Tools & Materials You’ll Need

- Compression tester kit (e.g., OTC 5605, ~$40-80) – Includes adapters for most spark plug holes

- Ratchet and spark plug socket (Size varies by engine; 5/8″ or 13/16″ are common)

- Extension bar (6″ and 12″ lengths)

- Spark plug wire removal tool (Optional but helpful for tight spaces)

- Battery charger or jump starter (Engine must crank at 250+ RPM for accurate results)

- Notepad and pen (To record readings)

- Compressed air (For cleaning spark plug wells)

- Safety glasses and gloves (Non-negotiable)

Step-by-Step: How to Perform a Compression Test

Safety First:

- Never perform a compression test on a hot engine. Let it cool for at least 2 hours.

- Disconnect the fuel system to prevent accidental fuel spray (pull the fuel pump relay or unplug the injectors).

- Wear safety glasses—spark plug porcelain can shatter.

- Keep hands and tools clear of moving belts/pulleys while cranking.

Start with a warm engine (operating temperature). This ensures accurate readings, as cold engines can show falsely low compression. If the engine won’t start, run it for 10-15 minutes before shutting it off to test.

Prevent fuel spray by either:

- Pulling the fuel pump relay (check your owner’s manual for location), or

- Unplugging the fuel injectors (disconnect the wiring harness).

This step is critical—raw fuel spraying into cylinders is a fire hazard.

Remove every spark plug. This reduces cranking resistance and ensures consistent RPM during testing. Use compressed air to blow debris from the spark plug wells before removal to prevent dirt from entering the cylinders.

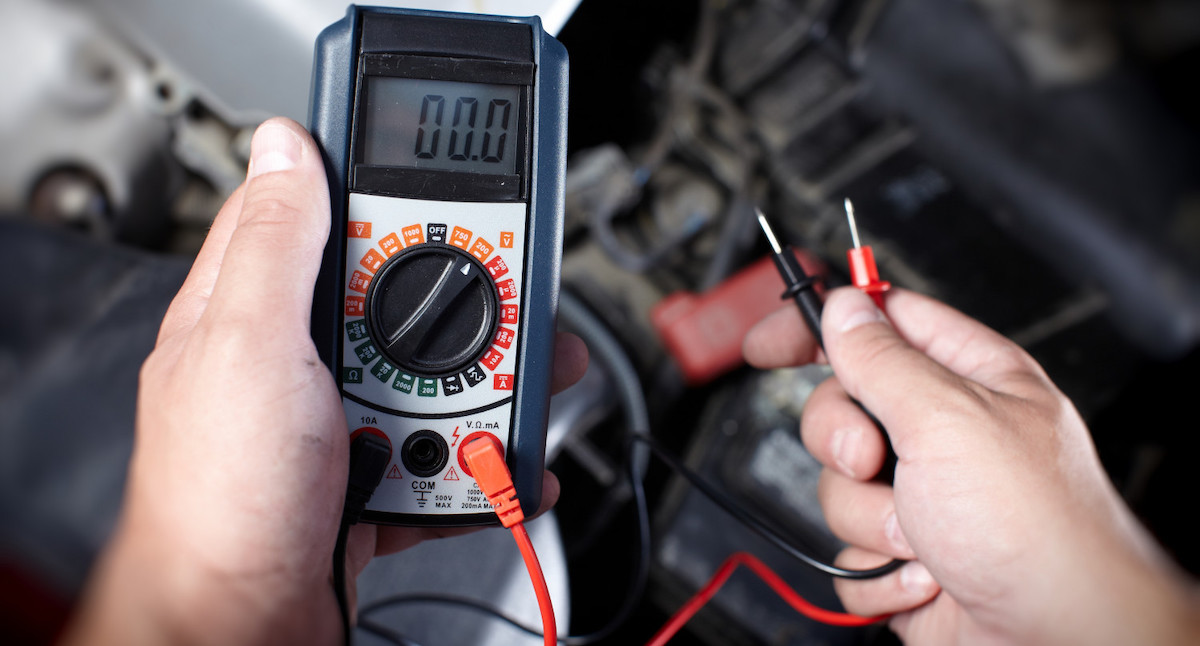

Screw the compression tester into the first spark plug hole. Ensure it’s hand-tight—no need to gorilla-wrench it.

[Insert image: Compression tester installed in spark plug hole]

Have a helper fully depress the throttle (or use a throttle stop tool) while you crank the engine for 5-10 seconds. The throttle must be WIDE OPEN to allow maximum airflow and accurate readings.

Watch the gauge—it should climb steadily and then plateau. Record the highest reading.

Test each cylinder 2-3 times to ensure consistency. Record all readings.

Compare your readings to the specifications for your engine (check your repair manual). As a general rule:

- Healthy engines: 125-175 PSI per cylinder

- Maximum variation between cylinders: 10%

- Example: If your highest reading is 150 PSI, no cylinder should be below 135 PSI.

Interpreting Your Compression Test Results

Here’s what your numbers are telling you:

| Reading | Likely Cause | Next Steps |

|---|---|---|

| All cylinders within 10% of each other, 125-175 PSI | Healthy engine | No action needed. If you’re troubleshooting a misfire, check ignition components or fuel delivery. |

| One cylinder low (20-30% below others) | Burnt valve, broken valve spring, or worn piston rings | Perform a leak-down test to pinpoint the issue. |

| Two adjacent cylinders low | Blown head gasket between cylinders | Check for coolant in oil or oil in coolant. Confirm with a chemical block test. |

| All cylinders low but equal | Worn piston rings (common in high-mileage engines) | Consider an oil control test or wet compression test (add oil to cylinders and retest). |

| One cylinder at 0 PSI | Hole in piston, broken valve, or severe head gasket failure | Remove the cylinder head for inspection. This is a major repair. |

Compression Test vs. Leak-Down Test: What’s the Difference?

While a compression test tells you if there’s a problem, a leak-down test tells you where the problem is. Here’s how they compare:

| Compression Test | Leak-Down Test |

|---|---|

| Measures maximum cylinder pressure | Measures how much pressure is lost and where |

| Quick and easy (30-45 minutes) | More involved (1-2 hours) |

| Requires basic tools | Requires compressed air and a leak-down tester (~$100) |

| Good for initial diagnosis | Essential for pinpointing issues (e.g., valves vs. rings) |

If your compression test reveals a problem, a leak-down test is the next step. It connects to the cylinder and pressurizes it with air, allowing you to hear (and sometimes see) where the air is escaping—through the valves, rings, or head gasket.

Common Mistakes to Avoid

- Testing a cold engine: You’ll get falsely low readings. Always test at operating temperature.

- Not disabling the fuel system: Raw fuel in the cylinders can give inaccurate readings and is a fire hazard.

- Using a weak battery: Slow cranking speeds = low compression readings. Use a charger if needed.

- Not removing all spark plugs: Extra drag from other cylinders will skew your results.

- Ignoring the throttle position: The throttle must be WIDE OPEN during testing. A closed throttle restricts airflow and lowers readings.

Cost Analysis: DIY vs. Professional Compression Test

| Item | DIY Cost | Professional Cost |

|---|---|---|

| Compression tester kit | $40-80 (one-time purchase) | N/A |

| Labor (1 hour) | $0 | $80-150 |

| Total | $40-80 | $80-150 |

If you’re already experiencing symptoms like a [hard-starting engine](hard-starting-engine) or [engine oil burning](engine-oil-burning), a compression test is a no-brainer. For the cost of a single diagnostic hour at a shop, you can buy a tester and use it for years.

FAQs About Engine Compression Tests

There’s no set interval, but I recommend testing if you notice:

- Hard starting (especially when cold)

- Rough idle or misfires

- Excessive oil consumption

- White smoke from the exhaust (could indicate coolant in cylinders)

- Before purchasing a used car with 100,000+ miles

Yes, but you’ll need a diesel-specific tester (like the OTC 5626) and a way to disable the injectors. Diesel engines have much higher compression (300-500 PSI), so a standard gasoline tester won’t work.

First, retest to confirm the reading. If it’s consistently low:

- Perform a leak-down test to locate the leak.

- If it’s a valve issue, you may need a valve job (~$400-800).

- If it’s piston rings, you’re looking at an engine rebuild (~$1,500-3,000).

I’ve seen low compression fixed with something as simple as a stuck valve (try tapping it gently with a rubber mallet before panicking).

It depends on the cause:

- Head gasket replacement: $1,200-2,000

- Valve job: $400-800

- Piston rings: $1,500-3,000 (requires engine removal)

- Cracked head: $500-1,500 (plus labor)

Always get a second opinion before committing to major repairs. I’ve seen shops recommend engine swaps for issues that a $200 valve adjustment could fix.

Final Thoughts: Is a Compression Test Worth It?

Absolutely. For less than $50, you can diagnose issues that would cost hundreds (or thousands) to guess at. I’ve saved customers thousands of dollars by catching simple valve adjustments or head gasket leaks before they turned into full-blown engine failures.

If you’re experiencing a [hard-starting engine](hard-starting-engine), [engine oil burning](engine-oil-burning), or a persistent misfire, a compression test should be your first step. It’s not just about fixing problems—it’s about understanding your engine’s health and making informed decisions.

And remember: A “bad” compression test doesn’t always mean a death sentence for your engine. I’ve seen engines with 90 PSI in every cylinder run for another 50,000 miles with the right care. It’s all about knowing what you’re dealing with.