Last Tuesday afternoon, a regular customer rolled into my bay with her 2016 Honda CR-V—158,000 miles on the odometer. “It’s doing that thing again,” she said, looking worried. I knew exactly what “that thing” meant because I’d cleared the same check engine light three weeks prior. The engine would stumble and hesitate during highway merges, almost like someone was tapping the brakes on her fuel supply.

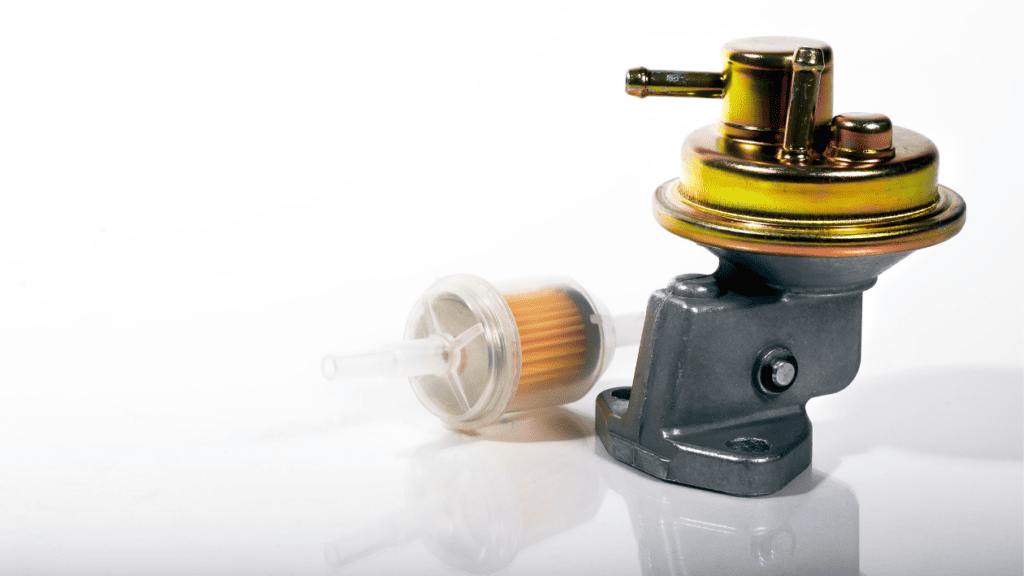

Understanding Your Fuel Filter’s Job

Before we dive into the symptoms, let me explain what’s actually happening inside that little canister. Your fuel filter sits between the fuel tank and the engine—either along the frame rail, inside the tank as part of the pump assembly, or under the hood near the firewall depending on your vehicle.

Every time you fire up your engine, this filter catches rust particles from your tank, dirt that snuck past the fuel cap, debris from old gasoline, and contaminants from questionable gas stations. Modern fuel injectors have tolerances measured in microns—we’re talking about gaps smaller than a human hair. Even a tiny particle can jam an injector wide open or closed, causing misfires, rough running, and expensive repairs.

I’ve cut open hundreds of old fuel filters in my career, and what’s inside always surprises people. Dark brown sludge, metal shavings, paint chips from corroded tanks, and once—I kid you not—what looked like pieces of a decomposed rodent. Your filter is doing critical work every single day, and when it gets overwhelmed, your engine pays the price.

Symptom #1: Engine Sputtering at Highway Speeds

This is the number one symptom I see, and it scared the hell out of that CR-V owner. You’re cruising at 65 mph on the highway, and suddenly the engine starts bucking and surging like it’s gasping for air. The tachometer needle bounces, power drops, then everything smooths out again. Five minutes later, it happens again.

Here’s what’s happening: when you’re at highway speeds, your engine demands maximum fuel flow. A partially clogged filter can handle idle and city driving, but ask it to flow 40-60 PSI at high volume, and it chokes. The restriction causes fuel pressure to drop below specification—often down to 35-45 PSI when it should be maintaining 55-60 PSI on most modern vehicles.

I’ve tested this scenario dozens of times with a fuel pressure gauge. With the engine at idle, pressure looks perfect. Rev it up to 3,000 RPM under load, and watch that needle plummet. The fuel pump is screaming, trying to push fuel through a filter that’s 70% blocked, and your engine computer starts pulling timing and limiting power to prevent lean misfires.

Don’t confuse this with ignition system problems. Fuel starvation sputtering happens under sustained load—accelerating up a hill, passing, or maintaining high speed. Ignition misfires are more random and occur at all speeds. If you want to learn more about other causes, check out our guide on [engine sputtering fixes](engine-sputtering-causes) for a complete diagnostic approach.

Symptom #2: Hard Starting, Especially When Cold

Your car cranks and cranks and cranks before finally catching. Once it starts, it might run fine, but that extended cranking time is your first clue something’s restricting fuel flow. Cold starts are particularly telling because that’s when your engine needs the richest fuel mixture—and a clogged filter can’t deliver it.

I had a 2014 Ford F-150 with the 3.5L EcoBoost in my shop last month with this exact complaint. The owner said it took 6-8 seconds of cranking every morning, but started immediately when the engine was warm. We hooked up a fuel pressure gauge and found the problem immediately: fuel pressure took 4-5 seconds to build from zero to the required 60 PSI because the filter was so restricted.

On a healthy system, fuel pressure should build to specification within 1-2 seconds of turning the key to “on” (before you even crank the engine). The fuel pump primes, pressure builds, and the engine fires right up. But when your filter is clogged, the pump has to work overtime just to overcome the restriction and fill the fuel rails.

For more detailed diagnostics on starting problems, I’ve written an extensive guide on [hard starting solutions](hard-starting-engine-diagnosis) that covers everything from fuel delivery to starter issues.

Symptom #3: Random Stalling at Idle or Low Speeds

You’re sitting at a red light, and suddenly the engine dies. Or you’re crawling through a parking lot at 5 mph, and the car just quits. The engine fires right back up when you restart it, but it’s embarrassing, frustrating, and makes you question your car’s reliability.

This symptom confused me early in my career until I understood the relationship between fuel filter restriction and fuel pump pressure regulation. Modern fuel systems maintain constant pressure using a pressure regulator—usually integrated into the fuel pump module on newer vehicles. When your filter is severely clogged, the pump can’t maintain stable pressure during rapid load changes.

At idle, your engine needs minimal fuel flow. But the instant you tip into the throttle—even slightly—fuel demand spikes. A clogged filter creates such high restriction that fuel pressure can’t respond quickly enough. The engine leans out momentarily, misfires, and stalls. By the time you restart it, the fuel system has had time to recover, so it fires right up.

I diagnosed this exact scenario on a 2017 Toyota Camry three weeks ago. The owner had taken it to two other shops who replaced the throttle body and cleaned the MAF sensor—neither fixed the stalling. I installed a fuel pressure gauge with a recording function and took it for a test drive. Every time the engine stalled, fuel pressure dropped from 58 PSI down to 41 PSI in less than half a second. New fuel filter solved it completely.

Symptom #4: Loss of Power During Acceleration

You step on the gas to merge onto the highway, and your car responds like it’s towing a trailer. The engine revs, but acceleration is sluggish. It feels like someone installed a governor that won’t let you go faster than 60 mph, even with the pedal buried.

This symptom drives people crazy because the car runs fine at steady speeds. It’s only when you demand power that the restriction becomes obvious. What’s happening is straightforward: your engine computer is smart enough to detect insufficient fuel delivery and goes into a protective mode called “limp mode” or power reduction mode.

Modern ECUs monitor fuel trim values constantly. When the computer sees it’s adding 20-25% more fuel than normal just to maintain proper air-fuel ratios (because pressure is low), it assumes something’s wrong and limits power output to prevent engine damage. I’ve seen engines pull timing, limit throttle opening, and even disable cylinders to protect themselves from running too lean.

The frustrating part? The check engine light might not even be on yet. I’ve tested vehicles with clear power loss from clogged fuel filters that had zero diagnostic trouble codes stored. The computer hasn’t crossed the threshold for setting a code, but the symptoms are undeniable.

Symptom #5: Rough Idle and Engine Vibration

Your engine used to idle smooth as glass. Now it shakes and vibrates like it’s missing on a cylinder. The steering wheel trembles, the whole car seems to rock slightly at stoplights, and you can feel the roughness through the floor.

Rough idle from a bad fuel filter is different from rough idle caused by worn engine mounts or misfiring spark plugs. Fuel starvation creates an inconsistent idle that varies in intensity. Sometimes it’s smooth, sometimes it’s rough, and you can’t predict when it’ll act up. This inconsistency is the key diagnostic clue.

I worked on a 2015 Nissan Altima last year where the owner had already spent $800 on new spark plugs, ignition coils, and a throttle body service at another shop. The rough idle persisted. I connected a fuel pressure gauge and watched it fluctuate between 48-58 PSI at idle when it should hold rock steady at 54 PSI. The filter was so clogged that every time the pump cycled, pressure would surge then drop.

Your fuel injectors deliver precise amounts of fuel based on expected fuel pressure. When that pressure is inconsistent, some cylinders run rich, others run lean, and your idle quality goes to hell. The engine computer tries to compensate with fuel trim adjustments, but it’s always playing catch-up with changing pressure.

Symptom #6: Decreased Fuel Economy

You’re filling up the tank more often, but your driving habits haven’t changed. Your normally efficient sedan that got 32 mpg is now struggling to hit 26 mpg. The fuel gauge seems to drop faster than it used to, and you’re spending noticeably more at the pump.

Here’s the counterintuitive part: a clogged fuel filter causes poor fuel economy even though it’s restricting fuel flow. How? Your engine computer compensates for low fuel pressure by increasing injector pulse width—keeping the injectors open longer to deliver the required fuel volume. This compensation works, but it’s inefficient.

Think of it like drinking through a clogged straw. You can still get the same amount of liquid, but you have to suck harder and longer. Your fuel system does the same thing, running the injectors longer and the pump harder, which actually increases fuel consumption while decreasing power output.

I tracked this on my scan tool with a 2018 Mazda CX-5 that came in for poor fuel economy. The owner calculated he’d lost 4-5 mpg over two months. Long-term fuel trims showed +18% correction—the computer was adding 18% more fuel than baseline to maintain proper combustion. After installing a new fuel filter, fuel trims dropped to +3%, and his fuel economy recovered within one tank of gas.

Symptom #7: Engine Misfires Under Load

The check engine light is flashing, your engine is running rough, and your scan tool shows multiple misfire codes: P0300 (random misfire), P0301, P0304, maybe P0306. You’re getting misfires on different cylinders that seem to rotate randomly. One day it’s cylinder 2 and 5, next week it’s 1 and 4.

This pattern—multiple random misfires that occur primarily under acceleration or load—is a classic fuel starvation signature. It’s different from a bad coil (which affects one cylinder consistently) or worn spark plugs (which usually show progressive degradation across all cylinders).

When fuel pressure drops below specification under load, some cylinders don’t receive enough fuel to ignite properly. Which cylinders misfire can vary based on injector flow rates (they’re never perfectly identical), fuel rail pressure distribution, and even how the engine computer sequences injector firing. The inconsistency is actually the diagnostic clue.

I’ve seen techs waste hours chasing misfire codes, replacing coils and plugs, only to find the root cause was fuel delivery. Three months ago, a 2016 Chevrolet Silverado came to my shop after the dealer quoted $1,800 to replace all eight ignition coils for chronic misfire codes. I spent $40 on a fuel pressure test and found pressure dropping to 42 PSI under load when GM specifies 58-62 PSI for that 5.3L engine. New fuel filter, problem solved, $89 total with labor.

Symptom #8: Check Engine Light with Fuel System Codes

Finally, your check engine light illuminates. You pull codes and find P0171 (system too lean, bank 1), P0174 (system too lean, bank 2), P0087 (fuel rail pressure too low), or P0089 (fuel pressure regulator malfunction). These are your engine computer’s way of screaming “I’m not getting enough fuel!”

Lean condition codes are particularly common because when fuel pressure is insufficient, the air-fuel mixture becomes lean (too much air, not enough fuel). Your oxygen sensors detect this, report it to the ECU, and eventually a code sets. The computer tries to compensate by richening the mixture, but there’s a limit to how much correction it can make.

P0087 is the most direct code—it literally means the fuel pressure sensor is reporting pressure below specification. If you see this code, your diagnostic path is clear: test actual fuel pressure with a mechanical gauge, compare it to factory specifications, and trace the problem to either the filter, pump, pressure regulator, or (rarely) a leaking fuel line.

That said, if you’re seeing lean codes (P0171/P0174) combined with any of the other symptoms I’ve described—sputtering, hard starting, power loss—the filter is a logical first step. It’s cheap, easy to replace on most vehicles, and often solves multiple symptoms simultaneously.

How to Confirm It’s Really Your Fuel Filter

Before you start buying parts, let’s verify the diagnosis. I’ve developed a systematic approach over the years that separates fuel filter problems from other fuel system failures. Here’s my shop procedure that you can replicate at home.

Fuel Pressure Test (The Gold Standard)

This is the definitive test. You need a fuel pressure test kit—available at AutoZone for about $30-50 or as a loaner tool for free with a deposit. The kit includes a gauge, various adapters for different fuel rail connections, and a bleed valve.

1 Locate your fuel rail test port. On most vehicles, this is a Schrader valve (looks like a tire valve) on the fuel rail near the injectors. Some vehicles require removing a plastic cap, others need an adapter to splice into the fuel line.

2 Relieve fuel pressure first. Pull the fuel pump fuse, start the engine, and let it die. This prevents gasoline from spraying everywhere when you connect the gauge. Have shop towels ready regardless—you’ll still get some spillage.

3 Connect the gauge using the appropriate adapter. Reinstall the fuel pump fuse. Turn the ignition to “on” without cranking and watch the gauge. Pressure should build within 2-3 seconds and stabilize. Compare to your vehicle’s specifications (check a repair manual or AllData).

4 Start the engine and test at idle. Pressure should remain stable. Note the reading. Normal ranges vary, but most modern systems run 40-65 PSI. Write down what you see.

5 Rev the engine to 2,500-3,000 RPM and watch for pressure drop. A healthy system maintains pressure or increases slightly. If pressure drops more than 5-7 PSI, you have a restriction—usually the filter or a failing pump.

6 Road test if possible. Some brave souls will zip-tie the gauge to the windshield wiper and go for a drive (with a helper watching the gauge). Under full throttle acceleration, pressure should remain stable. Any drop below specification confirms your problem.

| Test Condition | Normal Pressure | Clogged Filter | Failing Pump |

|---|---|---|---|

| Key On, Engine Off | Full spec (e.g., 55-60 PSI) | Slow to build, may reach spec | Low or zero pressure |

| Idle | Stable at spec | At or slightly below spec | Below spec |

| 2,500 RPM | Stable or slight increase | Drops 8-15+ PSI | Drops significantly |

| Full Throttle | Maintains spec | Drops 10-20+ PSI | Very low or zero |

Visual Inspection Method

If you can access your fuel filter without disassembling half the car, a visual inspection tells you a lot. On older vehicles with external filters along the frame rail or under the hood, this is easy. On newer vehicles with in-tank filters, you’re out of luck without dropping the tank.

Look for rust streaks coming from the filter outlet. Check for bulging—I’ve seen filters so clogged they literally swelled up from internal pressure. Shake it gently; you shouldn’t hear sloshing sounds or rattling debris. Compare it to a new filter; if yours is noticeably heavier, it’s full of trapped contaminants.

Fuel Pump Sound Test

This is less scientific but surprisingly useful. When you turn the key to “on,” listen carefully at the fuel filler door or near the rear seat. You should hear a smooth, consistent whir for 2-3 seconds as the pump primes. A clogged filter makes the pump work harder, often creating a louder, higher-pitched whine or a laboring sound.

I’ve diagnosed several clogged filters just by this sound difference. A healthy pump sounds like a quiet electric motor. A pump pushing through a restricted filter sounds strained, almost angry. If your pump has always been quiet and suddenly sounds noticeably louder, that’s your clue.

When to Replace vs. When to Get Professional Help

Here’s where I give you the straight truth about whether this is a DIY job or a professional project. I’ve been on both sides—I’ve spent my career fixing cars, but I also own vehicles where I pay someone else to work on them. Some jobs just aren’t worth the hassle.

Easy DIY Territory (1-2 Hours, Basic Tools)

If your vehicle has an external fuel filter along the frame rail, under the hood, or easily accessible under the vehicle, this is absolutely a DIY job. Vehicles that typically have external filters include:

- Most Ford trucks and SUVs through 2008

- Chevrolet/GMC trucks through 2007

- Toyota Tacoma, 4Runner, and Tundra through 2015

- Older Honda and Nissan models (pre-2010)

- Most diesel vehicles (filters are much more accessible)

For these vehicles, you need basic hand tools, safety glasses, a drip pan, and about 60-90 minutes. The filter costs $20-45, and you’ll save $80-120 in labor charges by doing it yourself. I’d rate this difficulty as 3 out of 10—easier than changing spark plugs, harder than an oil change.

Professional Territory (3-6 Hours, Specialized Tools)

If your fuel filter is integrated into the fuel pump assembly inside the tank, pay someone. Modern vehicles from 2010 onward increasingly use this design to reduce emissions and improve fuel system efficiency. You’re looking at:

- Dropping the fuel tank (major pain)

- Disconnecting multiple electrical connectors and fuel lines

- Working with a full tank of gasoline (extremely dangerous)

- Potentially needing a fuel tank sending unit wrench (special tool)

- Risk of damaging fuel level sensors, wiring, or lines

Professional shops charge $300-600 for this job depending on labor rates and parts cost. Yes, it’s expensive, but consider this: I’ve seen DIYers crack fuel tanks, damage sending units, create fuel leaks, and end up paying double to fix their mistakes plus the original problem.

Diesel Engines (Unique Considerations)

Diesel fuel filters are a completely different animal. They’re larger, accessible, and usually require two filters—a primary and a secondary. However, you must prime the system after replacement to purge air, which can be tricky without the right procedure.

I replace diesel fuel filters on my shop trucks every 15,000-20,000 miles religiously. Diesel fuel attracts water, which devastates injection systems that can cost $4,000-8,000 to repair. If you own a diesel, learn to change your own filters. It’s easier than a gas engine filter, takes 30 minutes, and your truck will thank you.

Cost Breakdown: DIY vs. Professional

Let’s talk real numbers based on what I see daily in my shop and what I pay when I buy parts.

DIY External Filter Replacement

- Fuel Filter (OEM): $25-65 depending on vehicle

- Fuel Filter (Aftermarket – Bosch, WIX, Mann): $15-35

- Fuel Line Disconnect Tool Set (if needed): $15-25 (one-time purchase)

- Shop Towels & Gloves: $8

- Safety Glasses: $5 (if you don’t have them)

- Total DIY Cost: $53-128

- Time Required: 1-2 hours

- Difficulty: 3/10 (Basic mechanical skills)

Professional External Filter Replacement

- Parts (filter): $35-75

- Labor (0.8-1.5 hours at $100-150/hr): $80-225

- Shop Supplies Fee: $8-15

- Total Professional Cost: $123-315

- Your Savings by DIY: $70-187

In-Tank Filter/Pump Assembly Replacement

- Fuel Pump Assembly (includes filter): $200-600

- Labor (2.5-5 hours at $100-150/hr): $250-750

- Shop Supplies & Tank Straps (if needed): $25-60

- Total Professional Cost: $475-1,410

- This is NOT a recommended DIY job for most people

Diesel Fuel Filter Replacement

- Primary & Secondary Filters (OEM): $45-120

- Priming Pump or Hand Primer: $0 (usually built-in)

- Total DIY Cost: $45-120

- Professional Cost: $150-280

- Time Required: 30-60 minutes

- Frequency: Every 15,000-20,000 miles

The math is clear for external filters—you’re saving $70-190 in labor costs for a relatively simple job. For in-tank assemblies, the cost is brutal either way, but the risk of DIY mistakes makes professional service worth it unless you’re very experienced.

The Hidden Cost of Ignoring a Bad Fuel Filter

Here’s what nobody tells you about delaying this repair. That $35 fuel filter you’re avoiding? It’s slowly destroying components that cost 10-20 times more to replace.

Your fuel pump is designed to move liquid fuel, not fight against resistance. When the filter clogs, the pump works harder, runs hotter, and wears out faster. A fuel pump that should last 150,000 miles might fail at 80,000 miles because it spent years straining against a clogged filter. I’ve replaced countless fuel pumps where the actual pump was fine, but it burned out from overwork.

That same 2016 CR-V from my opening story? The owner saved $45 by skipping the fuel filter replacement at 100,000 miles. At 158,000 miles, her fuel pump failed. The pump itself cost $380, plus $420 in labor to drop the tank, plus $45 for the filter we should have changed years ago. Total bill: $845. All to save $45 and an hour of labor back when the job was easy.

Fuel injectors are another casualty. Running lean damages injector tips, causes carbon buildup, and eventually leads to stuck or leaking injectors. I’ve seen $150/each injectors ruined by fuel starvation from a clogged filter. On a V6 or V8, you’re looking at $900-1,200 in parts alone, plus 3-4 hours of labor. The domino effect of one neglected maintenance item is staggering.

Fuel Filter Maintenance Schedule

Let’s establish realistic intervals based on actual vehicle requirements and real-world conditions. Manufacturer recommendations vary wildly, and some modern vehicles claim “lifetime” filters—which is automotive industry speak for “we want you to buy a new car before it needs service.”

| Vehicle Type | Ideal Interval | Maximum Interval | Notes |

|---|---|---|---|

| Gasoline, External Filter | 30,000 miles | 50,000 miles | Every 2-3 years minimum |

| Gasoline, In-Tank “Lifetime” | 80,000-100,000 miles | 120,000 miles | Inspect at pump replacement |

| Diesel Engines | 15,000-20,000 miles | 25,000 miles | More frequent in winter |

| Flex-Fuel Vehicles (E85) | 20,000-25,000 miles | 35,000 miles | Ethanol attracts water |

| Older Vehicles (Pre-2000) | 20,000-30,000 miles | 40,000 miles | Metal tanks rust internally |

These intervals assume normal driving conditions and quality fuel. If you frequently buy gas from questionable stations, drive in dusty environments, or let your tank run near empty regularly (which stirs up sediment), cut these intervals by 25-30%.

Choosing the Right Replacement Filter

Not all fuel filters are created equal, and I’ve learned this lesson the expensive way. Here’s my honest assessment of what works and what doesn’t after installing hundreds of filters across dozens of vehicle makes.

OEM vs. Aftermarket: The Reality

OEM (Original Equipment Manufacturer) filters are made by the same companies that built your vehicle’s fuel system. They’re spec’d to match flow rates, filtration levels, and pressure ratings exactly. The downside? They cost 50-100% more than aftermarket options.

For everyday vehicles where I’m not particularly worried about performance or longevity, quality aftermarket filters work fine. I’ve had excellent results with:

- Bosch: My go-to for German vehicles, but they make great universal filters too

- WIX/NAPA Gold: Same filter, different boxes. Excellent filtration, competitive pricing

- Mann Filter: Premium German engineering, slightly cheaper than OEM

- ACDelco (GM Professional): OEM quality for GM vehicles at lower prices

Filters I avoid completely: Fram (inconsistent quality), generic AutoZone/O’Reilly house brands, and anything that costs under $12 for a standard application. Fuel filters are not the place to save $8. I’ve seen cheap filters collapse internally, split at the seams, and pass debris that damages injectors.

For Performance or Luxury Vehicles

If you own a BMW, Mercedes, Audi, Lexus, or any performance vehicle, buy OEM filters. These fuel systems operate at higher pressures (up to 80-90 PSI for direct injection systems), have tighter tolerances, and don’t tolerate inferior parts. I’ve seen aftermarket filters cause erratic idle, misfires, and check engine lights on European cars that ran perfectly with OEM parts.

The $60 BMW fuel filter is expensive, but it’s infinitely cheaper than the $1,200 high-pressure fuel pump it protects or the $2,800 set of direct injectors that fail when contaminated fuel gets through.

Step-by-Step: Replacing an External Fuel Filter

Let me walk you through the process for a typical external filter replacement. I’ll use a 2005 Ford F-150 as an example because it’s representative of millions of vehicles still on the road with accessible filters.

Tools and Materials Needed

- Fuel filter (specific to your vehicle year/model)

- Fuel line disconnect tools (specific size for your vehicle, usually 3/8″ and 5/16″)

- Flare nut wrenches or line wrenches (if your filter uses threaded connections)

- Combination wrenches (10mm, 12mm, 14mm typically)

- Drain pan (at least 2-quart capacity)

- Shop towels (have plenty—you’ll need them)

- Nitrile gloves and safety glasses

- Penetrating oil (PB Blaster or equivalent)

- Jack and jack stands (if filter is underneath vehicle)

- Flashlight or work light

1 Relieve fuel system pressure. Locate your fuel pump fuse in the fuse panel (check your owner’s manual for location). With the engine off, remove the fuse. Start the engine and let it run until it dies—this usually takes 30-60 seconds. The fuel in the lines is now depressurized. Turn the key off and remove it.

2 Locate the fuel filter. On most trucks and body-on-frame SUVs, it’s along the driver’s side frame rail between the fuel tank and engine. On cars, check under the vehicle near the fuel tank or sometimes under the hood near the firewall. Follow the fuel line from the tank forward.

3 Spray connecting points with penetrating oil. If your filter uses threaded fittings, soak them with PB Blaster and let sit for 10-15 minutes. Rust and corrosion make these fittings incredibly difficult to loosen without rounding off.

4 Position your drain pan underneath the filter. You’ll get 2-4 ounces of fuel spillage minimum, possibly more if the filter is full. Have shop towels ready to catch drips.

5 Disconnect the inlet line. If using quick-disconnect fittings (most common on modern vehicles), insert the appropriate size disconnect tool into the fitting, push the tool toward the filter, and pull the line straight out. Fuel will drip—this is normal. If using threaded fittings, use a flare nut wrench to carefully loosen the fitting while holding the filter body with another wrench to prevent twisting.

6 Disconnect the outlet line using the same method. Mark the lines with tape if they look similar—inlet vs. outlet matters, and some filters are directional (there’s usually an arrow showing flow direction).

7 Remove the filter mounting bracket (usually one or two bolts). Keep track of any spacers or insulators—they prevent vibration and must be reinstalled exactly as they came off.

8 Note the filter orientation. Look for flow direction arrows on the old filter. Take a photo with your phone if helpful. The arrow points toward the engine (from tank to engine).

9 Install the new filter in the correct orientation. Many filters have different-sized fittings on each end to prevent backward installation, but not all do. Double-check that arrow.

10 Connect the fuel lines. Quick-disconnects should click audibly when fully seated—give them a firm tug to verify they’re locked. Threaded fittings should be tightened to manufacturer spec (usually 18-22 ft-lbs for fuel lines), but if you don’t have a torque wrench, snug them firmly plus about 1/4 turn. Don’t overtighten—you’ll split the fitting.

11 Reinstall the mounting bracket with all original spacers and insulators. Torque the mounting bolts appropriately for your vehicle (check a manual if unsure).

12 Reinstall the fuel pump fuse. Turn the key to “on” (don’t crank) and let the pump prime for 2-3 seconds. Turn the key off. Repeat this cycle 3-4 times to build pressure. Check all connections for leaks—look for drips and sniff for gasoline smell.

13 Start the engine. It might take longer than usual (5-10 seconds of cranking) as the system purges any trapped air. Once running, let it idle for 2-3 minutes while checking underneath for leaks. Rev the engine a few times and recheck.

14 Test drive the vehicle. Drive for 10-15 minutes, including highway speeds if possible. Listen and feel for the symptoms you were experiencing before. They should be completely gone.

Total job time for someone who’s done this before: 30-45 minutes. First-time DIYer: 60-90 minutes. Take your time, don’t rush, and remember that patience prevents mistakes.

What If Replacing the Filter Doesn’t Fix It?

Sometimes you replace the filter, and the symptoms persist. This happened to me on my own personal truck two years ago, and I felt like an idiot. The filter was clogged, but it wasn’t the only problem. Here’s how to diagnose further.

Failing Fuel Pump

If you replaced the filter and still have fuel pressure issues, the pump itself is likely worn out. Remember that clogged filter scenario from earlier—it may have already damaged your pump. Test fuel pressure again with the new filter installed. If pressure is still low or drops under load, you’re looking at pump replacement.

Fuel pump failure symptoms overlap significantly with clogged filter symptoms, which is why pressure testing is crucial. The pump costs 5-10 times more than the filter, so you want to be absolutely certain before replacing it. If you’re interested in learning more, our comprehensive guide on [fuel pump problems](fuel-pump-problems-diagnosis) covers everything from diagnosis to replacement.

Clogged or Leaking Fuel Injectors

If the filter replacement fixed your power loss and misfires but you still have rough idle or poor fuel economy, suspect the injectors. Running with low fuel pressure for extended periods causes injector varnishing and carbon buildup. Professional injector cleaning costs $180-300 and works about 60% of the time in my experience.

Damaged Fuel Pressure Regulator

On return-type fuel systems (less common on modern vehicles), a bad pressure regulator causes symptoms identical to a clogged filter. The regulator maintains constant pressure by routing excess fuel back to the tank. When it fails, pressure fluctuates wildly. Check for fuel in the vacuum line connected to the regulator—that’s a dead giveaway.

Contaminated Fuel Tank

If your new filter clogs again within a few thousand miles, your tank is full of rust and debris. This requires tank removal, thorough cleaning or replacement, and fresh fuel. It’s an expensive fix ($600-1,200 for tank replacement), but sometimes necessary on older vehicles with steel tanks.

Frequently Asked Questions

How long does a fuel filter last before it needs replacement?

For vehicles with external fuel filters, plan on replacement every 30,000-40,000 miles or every 2-3 years, whichever comes first. In-tank “lifetime” filters typically last 80,000-120,000 miles but should be inspected if the fuel pump requires replacement. Diesel engines need filter changes every 15,000-20,000 miles due to water accumulation and higher contamination levels in diesel fuel.

These intervals assume normal driving conditions and quality fuel. Shorten intervals by 25-30% if you frequently run low on fuel, drive in dusty environments, or buy gas from questionable stations. I’ve seen filters on work trucks operating in construction zones clog at 20,000 miles, while highway-driven vehicles go 50,000+ miles without issues.

Can I drive with a clogged fuel filter?

Technically yes, but I strongly advise against it—especially on highways. A severely clogged filter creates dangerous situations: sudden power loss during passing maneuvers, unexpected stalling in traffic, and unreliable starting when you’re in a hurry. Beyond safety concerns, continuing to drive damages your fuel pump by making it work harder against resistance, potentially turning a $35 filter problem into a $400-800 pump replacement.

If you’re experiencing symptoms, limit driving to essential trips at lower speeds until you can address the issue. I’ve had customers experience complete fuel pump failure while driving—the engine dies, power steering and brakes become difficult to operate, and you’re suddenly coasting to a stop hoping there’s a safe place to pull over.

What’s the difference between symptoms of a bad fuel filter vs. bad fuel pump?

This confuses people constantly because the symptoms overlap significantly. Here’s how I differentiate them: clogged fuel filters typically cause problems under sustained load (highway driving, long hills) and the symptoms develop gradually over weeks or months. The engine maintains some power but struggles to perform at maximum demand.

A failing fuel pump, on the other hand, creates more random symptoms that occur regardless of load. The engine might die suddenly at idle, fail to start when hot, or experience complete power loss without warning. Pump failures also tend to be more abrupt—your car runs fine one day and won’t start the next. The only definitive way to distinguish them is fuel pressure testing under various conditions, which is why I always start diagnostics with a pressure gauge attached.

Will a clogged fuel filter throw a check engine light?

Not always, which frustrates both technicians and vehicle owners. Your check engine light illuminates when the engine computer detects a problem that exceeds programmed thresholds. A partially clogged filter might not trigger codes even though it’s causing noticeable symptoms. However, as restriction worsens, you’ll eventually see codes like P0171/P0174 (system too lean), P0087 (fuel rail pressure too low), or P030X (misfire codes).

I’ve diagnosed dozens of clogged filters on vehicles with zero stored codes. The engine runs poorly, fuel pressure is 10-15 PSI below specification, but the computer hasn’t crossed the threshold to set a fault code. This is why scan tool data is more useful than just reading codes—watching live fuel trims, pressure readings, and misfire counters reveals problems before codes appear.

Can a bad fuel filter cause the engine to overheat?

Indirectly, yes, though it’s not a direct cause-and-effect relationship. When a severely clogged filter creates lean conditions (too much air, not enough fuel), combustion temperatures increase significantly. Prolonged lean running generates excessive heat that the cooling system struggles to dissipate. Additionally, if the engine is misfiring badly from fuel starvation, unburned fuel can ignite in the catalytic converter, generating extreme heat that radiates back toward the engine.

That said, engine overheating from a clogged fuel filter is rare and usually indicates multiple compounding problems. I’d estimate I’ve seen this scenario maybe five times in fifteen years. If your engine is overheating, investigate cooling system problems first—thermostat, water pump, radiator, coolant level, and hoses—before blaming fuel delivery issues.

How much does fuel filter replacement cost at a shop?

For external fuel filter replacement, expect $90-180 at most independent shops, or $150-250 at dealerships. This includes parts ($20-60) and labor (0.5-1.0 hours). Some shops charge less, some more, depending on filter accessibility and local labor rates. I charge $125 for most standard applications, which includes the filter, labor, and a post-repair pressure test to verify the repair solved the problem.

In-tank fuel filter replacement or full pump assembly replacement is dramatically more expensive: $400-1,000 at independent shops or $600-1,400 at dealerships. The parts alone run $200-600 for the complete assembly, and you’re paying for 2.5-5 hours of labor to drop the fuel tank, access the pump, and reinstall everything. Some luxury vehicles exceed these ranges—I’ve quoted $1,800 for BMW fuel pump assemblies at the dealer.

Is it worth changing the fuel filter if my car runs fine?

Yes, absolutely, as preventive maintenance. Just because your car runs fine today doesn’t mean the filter isn’t slowly restricting flow. Remember, filters don’t fail overnight—they degrade gradually. By the time you notice symptoms, damage to the fuel pump may have already begun. Think of it like changing engine oil: your engine doesn’t make noise at 10,000 miles, but you still change the oil at 5,000 miles to prevent future problems.

If your fuel filter is accessible and inexpensive to replace, I recommend following the maintenance schedule religiously. Spending $100 every 30,000-40,000 miles prevents $500-1,000 fuel pump replacements and avoids the inconvenience of being stranded. For in-tank “lifetime” filters where replacement requires dropping the tank, I understand waiting until symptoms appear or until 100,000+ miles—the cost-benefit equation is different.

Can I clean and reuse a fuel filter instead of replacing it?

No, absolutely not, and I’ve never understood why people attempt this. Fuel filters use paper, synthetic fiber, or pleated membrane media that cannot be effectively cleaned. Even if you blow compressed air backward through the filter and some debris comes out, you haven’t restored filtration capability—you’ve just created channels through the clogged media. The filter will restrict flow immediately and may allow particles through that it would have trapped when new.

I’ve seen DIYers try everything: soaking filters in carburetor cleaner, reverse-flushing with solvents, even pressure-washing them. None of it works. Fuel filters cost $15-60 for most applications. The time spent trying to clean a filter, plus the risk of damaging your fuel system with inadequate filtration, makes this a completely counterproductive exercise. Just buy a new filter—it’s the cheapest insurance policy your fuel system can have.

Final Thoughts from the Shop

After fifteen years of diagnosing fuel system problems, I’ve learned that most people ignore their fuel filter until it forces them to pay attention. That sputtering on the highway, the rough idle at stop lights, the hesitation during acceleration—these aren’t quirks of an aging vehicle. They’re warning signs that your fuel system is crying out for help.

The CR-V owner from my opening story learned this lesson the expensive way, but you don’t have to. Her $45 deferred maintenance turned into an $845 repair bill and two days without her vehicle. I see this pattern constantly: owners skip the cheap, easy maintenance and end up paying ten times more for emergency repairs.

Here’s my perspective after staring at fuel systems week after week: fuel filters are among the most neglected maintenance items on modern vehicles, yet they’re critical to fuel system longevity and engine performance. For the cost of dinner for two at a mid-range restaurant, you can prevent problems that cost as much as a vacation.

If you’re experiencing any of the eight symptoms I’ve detailed—sputtering, hard starting, stalling, power loss, rough idle, poor fuel economy, misfires, or check engine lights with fuel codes—test your fuel pressure first. A $30 pressure gauge and twenty minutes of diagnostic time will tell you definitively whether the filter is the problem. If pressure drops under load, replace the filter immediately.

For those with accessible external filters, this is an easy Saturday morning DIY project. Take your time, follow safety protocols, and you’ll save $80-150 in labor charges while gaining the satisfaction of maintaining your own vehicle. For in-tank filters integrated with the fuel pump, I recommend professional service—the complexity and risk aren’t worth the money you’d save.

Most importantly, don’t wait for symptoms to appear. If you can’t remember the last time your fuel filter was changed, or if your vehicle has exceeded the recommended interval, schedule this maintenance now. Your fuel pump will last longer, your engine will run better, and you’ll avoid the stress of unexpected breakdowns.

The fuel filter is a small part with enormous responsibility. Treat it with the respect it deserves, and it’ll help your vehicle run reliably for years to come. Ignore it, and you’ll eventually end up in my shop with a much bigger bill than the simple filter replacement you should have done months ago.

Stay safe out there, maintain your vehicles proactively, and remember: an ounce of prevention is worth a pound of cure—especially when that cure costs $800 and leaves you without transportation for two days.