It was a scorching July afternoon when Sarah’s 2015 Honda Accord rolled into my bay with the AC blasting—or at least trying to. The compressor was cycling on and off, the battery light flickered occasionally, and she mentioned a “weird squealing” that started three days ago but went away. I popped the hood, and there it was: a serpentine belt so glazed and cracked it looked like a dried-up creek bed. The worst part? She’d just driven 200 miles from Denver to visit family.

What Exactly Is a Serpentine Belt and Why Does It Matter?

The serpentine belt—also called the drive belt or multi-accessory belt—is a single continuous belt that snakes around multiple pulleys to power your vehicle’s critical accessories. Unlike the old multi-belt systems from the ’80s and ’90s, modern vehicles use one belt to drive the alternator, power steering pump, water pump (on some models), AC compressor, and sometimes the air injection pump.

When this belt fails, everything stops. Your alternator quits charging, power steering dies, AC goes silent, and if your water pump is belt-driven, your engine overheats in minutes. I’ve seen a $35 belt failure turn into a $3,200 engine replacement because the driver ignored the warning signs and kept going after the belt snapped.

The Anatomy of Belt Failure

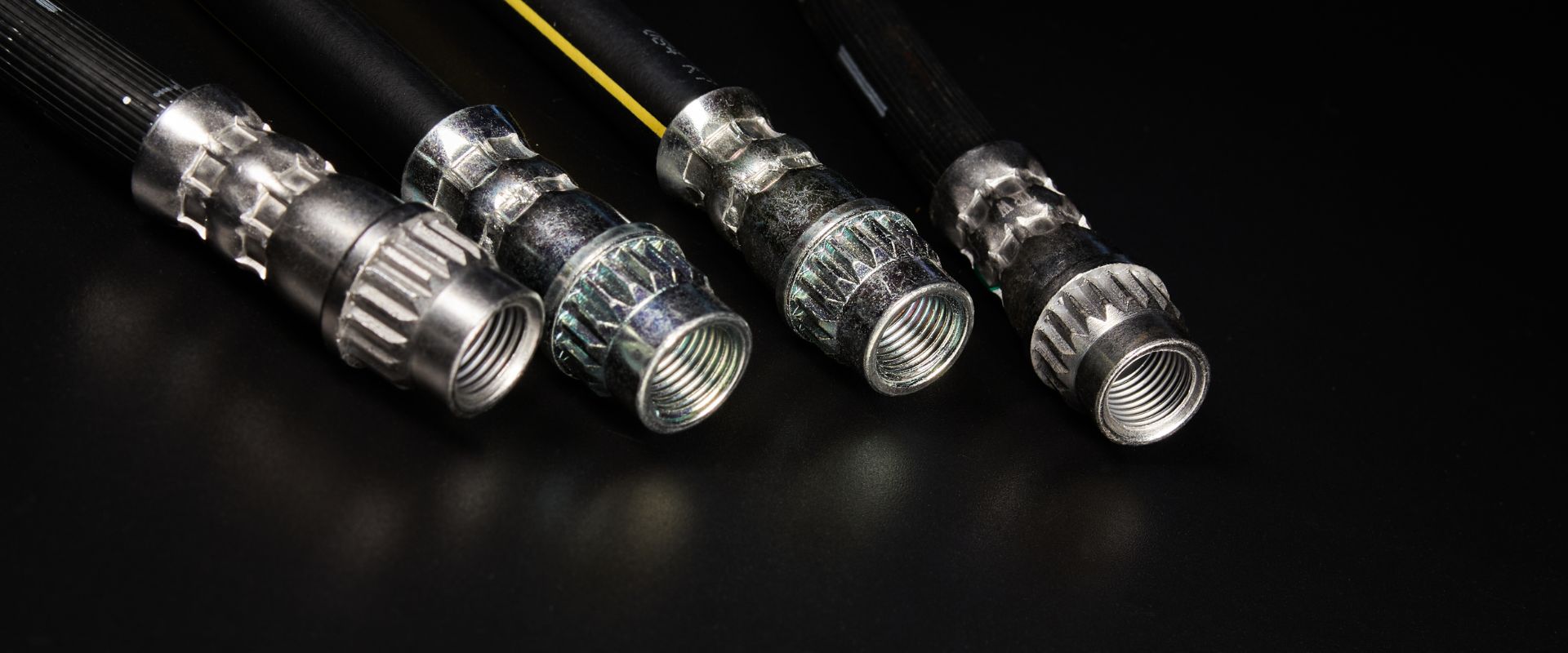

Serpentine belts are made from EPDM (Ethylene Propylene Diene Monomer) rubber with reinforcing cords—usually polyester or Kevlar. The ribs on the inside engage with grooved pulleys, and this constant flexing, temperature cycling, and tension eventually breaks down the rubber compound.

Here’s what happens over time: The rubber loses elasticity, the ribs develop microcracks, the belt glazes from heat and slippage, chunks start breaking off, and eventually the reinforcing cords separate or the belt shreds completely. The question isn’t if your belt will fail—it’s when.

Manufacturer-Recommended Serpentine Belt Mileage: The Official Numbers

Every automaker publishes recommended drive belt replacement intervals in the owner’s manual, but these numbers vary wildly. Let me break down what I see in my shop:

| Manufacturer | Recommended Interval | My Real-World Experience |

|---|---|---|

| Toyota/Lexus | 90,000-100,000 miles | Usually last 80,000-110,000 miles |

| Honda/Acura | 60,000-100,000 miles | Replace around 70,000-90,000 miles |

| Ford | 100,000 miles | Optimistic—check at 60,000, replace by 80,000 |

| GM (Chevrolet, GMC, Buick) | 150,000 miles | Rarely make it past 100,000 in my experience |

| Chrysler/Dodge/Jeep | 60,000-120,000 miles | Wide variation—inspect every 30,000 miles |

| BMW/Mercedes | 80,000-100,000 miles | Usually accurate if using OEM parts |

| Nissan/Infiniti | 60,000 miles | Conservative—often last 70,000-90,000 |

When to Replace Serpentine Belt: Real Warning Signs from the Field

Forget the mileage sticker for a minute. Your belt will tell you when it’s dying if you know what to look for. I teach my apprentices to inspect belts every oil change, and here’s what I look for:

Visual Inspection Indicators

Cracks in the Ribs: This is the number one sign. Small surface cracks are normal after 40,000 miles, but when cracks run deeper than 1/32 inch or span multiple ribs, replacement is overdue. I use the “bend test”—flex the belt back on itself and watch the ribs. If cracks open up wide enough to see through, that belt is living on borrowed time.

Glazing on the Belt Surface: A healthy belt has a slightly textured surface. A glazed belt looks shiny and smooth like glass. This happens from slipping on the pulleys due to incorrect tension or misalignment. Glazed belts squeal under load and lose grip. I’ve seen glazed belts at 35,000 miles that needed immediate replacement.

Missing Chunks or Pieces: If you see chunks missing from the ribs or edges fraying, stop driving the vehicle. This belt will fail soon—potentially within days or even hours. Last month, a customer brought in a Jeep Grand Cherokee with half an inch of rib missing. The belt lasted another 15 miles before shredding completely.

Uneven Wear Patterns: The belt should wear evenly across its width. If one edge is more worn than the other, you’ve got a pulley misalignment issue. Replace the belt, but also diagnose and fix the alignment problem or the new belt will fail prematurely.

Audible Warning Signs

Serpentine belts make noise when they’re failing, and different sounds indicate different problems. Understanding belt noise diagnosis can save you from a breakdown.

Squealing During Startup: That high-pitched squeal when you start the car on cold mornings usually means the belt is slipping. Early on, this might only happen when it’s cold and humid. As the belt ages, the squeal becomes constant. This is often the first audible warning that replacement is coming due.

Chirping at Idle: A rapid chirping sound, especially noticeable at idle with the AC on, typically indicates rib damage or a failing belt tensioner. I’ve traced probably 60% of chirping noises to worn tensioners rather than the belt itself, but both usually need replacement together.

Grinding or Rumbling: This isn’t the belt—it’s a bearing in one of the accessories (alternator, water pump, idler pulley, or tensioner). A failing bearing will destroy a perfectly good belt in under 1,000 miles. I’ve seen this scenario play out dozens of times: customer replaces belt, noise goes away for a week, then returns with a vengeance.

Performance-Related Symptoms

Battery Light Flickering: If your battery or charging light comes on intermittently, especially under load (AC on, headlights, etc.), the belt might be slipping on the alternator pulley. This happens before complete failure. I check belt tension and condition immediately when I see this symptom.

Power Steering Loss: Modern electric power steering has made this less common, but vehicles with hydraulic systems will experience heavy, difficult steering if the belt slips or fails. This is dangerous in traffic and should prompt immediate inspection.

AC Compressor Cycling: Like Sarah’s Accord in my opening story, a slipping belt can’t consistently drive the AC compressor clutch. The system cycles rapidly or blows warm air intermittently. This is often dismissed as an AC problem when it’s actually a dying belt.

Engine Running Hot: If your water pump is belt-driven (common on Toyota, Honda, and Subaru engines), a slipping or failing belt reduces coolant flow. You’ll see the temperature gauge creeping up, especially in stop-and-go traffic. This is serious—shut down immediately if you see this.

Factors That Destroy Serpentine Belt Lifespan

Two identical vehicles with identical mileage can have vastly different belt conditions. After diagnosing thousands of belt failures, I’ve identified the factors that kill belts prematurely.

Climate and Weather Extremes

Here in Colorado, we swing from -15°F winter mornings to 105°F summer afternoons. This temperature cycling is brutal on rubber compounds. I see belts fail 20,000-30,000 miles earlier than the same models in moderate climates like California or the Pacific Northwest.

Humidity matters too. High humidity causes belts to slip and glaze. Low humidity makes rubber brittle. The worst scenario? Phoenix summers where it’s 115°F and bone dry—I’ve seen belts there last only 45,000 miles.

Cold weather causes rubber to contract and lose flexibility. That morning squealing sound? It’s the belt slipping because it’s temporarily stiff from cold. Repeated cold starts accelerate wear.

Driving Patterns and Conditions

Short Trips: Vehicles that make primarily short trips (under 15 minutes) never fully warm up. The belt operates in less-than-ideal conditions, accumulating more cold starts and temperature cycles. I see premature belt wear on vehicles with high trip counts but moderate total mileage.

Stop-and-Go Traffic: Constant acceleration and deceleration, plus heavy AC use in traffic, keeps belt tension varying continuously. This flexing accelerates fatigue. Urban delivery vehicles and pizza delivery cars always have worse belt wear than highway cruisers.

Extreme Loads: Towing, carrying heavy loads, or driving in mountainous terrain increases accessory demands. The alternator works harder, the AC compressor struggles, and power steering pumps labor. This additional load stresses the belt. I replaced the belt on a Silverado 2500 used for heavy trailer hauling at just 52,000 miles—it looked like it had 100,000.

Maintenance History (or Lack Thereof)

Vehicles that receive regular maintenance have belts lasting 20-30% longer on average. Why? Because during routine service, we inspect and address minor issues before they become belt killers:

Tensioner Condition: A weak tensioner allows belt slippage, which generates heat and glazing. I replace tensioners with belts as standard practice on vehicles over 80,000 miles. The tensioner usually fails before the belt, then destroys the new belt.

Pulley Alignment: Misaligned pulleys create side loading that tears up belt edges. This happens from accidents, improper repairs, or worn engine mounts. I’ve seen misalignment destroy a new belt in under 5,000 miles.

Contamination: Oil leaks from valve covers, power steering pumps, or elsewhere coat the belt and cause premature deterioration. EPDM rubber is oil-resistant but not oil-proof. A belt contaminated with oil will slip, glaze, and fail early. Fix leaks immediately.

Belt Quality: OEM vs Aftermarket Reality

This is where I’m going to save you money and headaches. Not all serpentine belts are created equal, and the price difference is meaningful.

I stock three quality tiers in my shop:

OEM (Original Equipment Manufacturer) Belts: These are expensive—typically $60-$120 for the belt alone. But they’re engineered specifically for your vehicle and use premium EPDM compounds. Toyota, Honda, and BMW OEM belts consistently last 80,000-100,000+ miles in my experience. When a customer wants maximum belt life and has a vehicle they plan to keep long-term, I recommend OEM.

Premium Aftermarket (Gates, Continental, Dayco): These cost $30-$50 and represent 90% of what I install. Gates Green Stripe and Dayco Poly Rib belts are excellent quality and last 70,000-90,000 miles. Continental makes OEM belts for many manufacturers, so their aftermarket versions are essentially the same. This is my sweet spot for value and reliability.

Economy Aftermarket (Store Brands, Unknown Manufacturers): These $15-$25 belts from discount auto parts stores look identical but use inferior rubber compounds. I’ve personally tracked failure rates, and these economy belts fail 30-40% earlier than premium options. That $20 you saved costs you $150 in labor to replace it again in 35,000 miles instead of 70,000. Don’t do it.

The Complete Serpentine Belt Replacement Process

If you’re mechanically inclined and want to tackle this yourself, serpentine belt replacement is one of the more approachable DIY jobs. Here’s the complete process I follow in my shop.

Tools and Materials Required

Must-Have Tools:

- Serpentine Belt Tool or 3/8″ Breaker Bar – For releasing belt tensioner ($15-$35 at AutoZone)

- 15mm or 16mm Socket/Wrench – Most common tensioner sizes ($8 individual or included in sets)

- Flashlight or Work Light – Essential for seeing the belt routing ($10-$30)

- Phone Camera – To photograph belt routing before removal (free)

- Replacement Belt – Premium quality, correct part number ($30-$50 aftermarket, $60-$120 OEM)

Highly Recommended:

- Belt Wear Gauge – Measures rib depth accurately ($12-$20 at Amazon)

- Creeper or Cardboard – You’ll be working from underneath on some vehicles ($25-$40)

- Latex Gloves – Keeps your hands clean ($8 for 100-pack)

- Belt Dressing Spray – For initial break-in, prevents squealing ($6-$8, though I rarely use it)

Nice to Have:

- Pulley Alignment Tool – For checking pulley alignment ($45-$80, professional-grade)

- Tension Gauge – For verifying proper belt tension ($80-$150, usually unnecessary with automatic tensioners)

Step-by-Step Replacement Procedure

Step 1: Locate and Photograph the Belt Routing (5 minutes)

Open the hood and locate the belt routing diagram. Most vehicles have this decal on the radiator support or hood underside. It shows exactly how the belt wraps around each pulley. Take multiple photos with your phone from different angles. Trust me on this—I’ve had experienced techs forget the routing midway through the job. It’s embarrassing and time-consuming to figure it out later.

If there’s no diagram, sketch it yourself or look it up online. Never rely on memory alone.

Step 2: Identify the Belt Tensioner (3 minutes)

The tensioner is a spring-loaded pulley that maintains proper belt tension. It’s usually on the passenger side of the engine and has a square 3/8″ hole or a 15mm/16mm hex bolt in the center. On some vehicles (particularly Ford and GM trucks), the tensioner is accessed from underneath.

Trace the belt path and verify which pulley is the tensioner. It’s typically the pulley with the smoothest face (no grooves) and visible spring mechanism.

Step 3: Release Tensioner and Remove Old Belt (5-10 minutes)

This is the critical step. Insert your 3/8″ breaker bar or serpentine belt tool into the tensioner’s square hole (or socket onto the hex bolt). Rotate the tensioner against its spring tension—this will be clockwise on most vehicles, counterclockwise on some (check which direction relieves tension).

You’ll need to apply significant force—30-40 pounds typically. The tensioner should move smoothly. If it feels stuck or grinding, stop and investigate. Once you’ve rotated it enough to create slack, slip the belt off the nearest pulley (usually the alternator or AC compressor).

Slowly release the tensioner and remove the belt from all other pulleys. Inspect the tensioner while you’re here—it should snap back firmly to its rest position. If it moves slowly or doesn’t return fully, replace it along with the belt.

Step 4: Inspect All Pulleys and Components (10-15 minutes)

With the belt off, this is your opportunity to inspect everything the belt touches. Spin each pulley by hand:

- They should rotate smoothly and quietly

- No grinding, roughness, or wobble

- No side-to-side play

- All pulleys should be aligned in the same plane

Check the tensioner pulley bearing by spinning it. A bad bearing makes a rough, grinding sound or has excessive drag. I replace the tensioner assembly on any vehicle over 80,000 miles as preventive maintenance. The tensioner costs $40-$80, and replacing it now saves you from doing this job again in 20,000 miles when the tensioner fails and shreds your new belt.

Look for oil contamination on pulleys. If you find oil, identify the source and fix it before installing the new belt. Common culprits: valve cover gaskets, power steering pumps, crankshaft front seals.

Step 5: Install the New Belt (10-20 minutes)

Starting at the crankshaft (the lowest, largest pulley), route the new belt according to your photo or diagram. Work your way around, ensuring the belt seats properly in each pulley’s grooves. The ribbed side goes against grooved pulleys; the smooth backside goes against smooth pulleys (usually just the tensioner).

Leave the tensioner pulley for last—it’s the one you’ll pull back to slip the belt over. Once the belt is on all other pulleys, pull the tensioner back again with your tool and slip the belt over the tensioner pulley. Ensure it’s centered and seated in the grooves.

Slowly release the tensioner. The belt should be tight with no slack anywhere. Verify the belt is properly seated on every pulley—look at the belt from the side and make sure it’s not riding up on the edge of any pulley.

Step 6: Verify Installation and Test (5-10 minutes)

Before starting the engine, manually rotate the crankshaft two complete revolutions using a socket on the crankshaft bolt. This tests the belt routing without engine power. Watch for the belt to jump off any pulley or ride improperly. If anything looks wrong, stop and re-check the routing.

Reconnect the battery and start the engine. Listen for any squealing, chirping, or unusual noises. Let it idle for 30 seconds, then turn on the AC, headlights, and other accessories to load the belt. It should remain quiet.

After the test drive (10-15 minutes of normal driving), re-check the belt. It’s normal for a new belt to “seat” itself and look slightly different after the first drive. Verify it’s still properly positioned on all pulleys.

Time and Difficulty Assessment

For a DIYer with basic mechanical skills, expect 45 minutes to 1.5 hours for straightforward applications (Toyota Camry, Honda Accord, basic GM or Ford engines). Complex engine bays (Subaru, transverse V6 engines, anything German) can take 2-3 hours if you need to remove other components for access.

In my shop, I quote 0.5-0.8 hours labor for most serpentine belt replacements, which means I’m turning them in 30-45 minutes. But I’ve done thousands of these—don’t feel bad if it takes you longer.

Serpentine Belt Replacement Cost Analysis

Let’s talk money. Serpentine belt replacement costs vary wildly depending on your vehicle, location, and whether you DIY or hire a professional.

DIY Cost Breakdown

- Premium Aftermarket Belt (Gates, Dayco): $30-$50

- OEM Belt: $60-$120

- Economy Belt (not recommended): $15-$25

- Belt Tensioner (if needed): $40-$120

- Idler Pulleys (if needed): $25-$60 each

- Tools (if you don’t own them): $25-$50 one-time purchase

Total DIY Cost: $30-$75 for belt only, $100-$250 if replacing tensioner and pulleys

Professional Shop Costs

- Independent Shop Belt Replacement: $100-$200 (parts + labor)

- Dealership Belt Replacement: $150-$300 (OEM parts + higher labor rate)

- Belt + Tensioner Replacement: $200-$400

- Complete Belt Service (belt, tensioner, idlers): $300-$600

Labor Rate Factor: Most shops charge $90-$150/hour. Belt replacement typically takes 0.5-1.0 hours.

Here’s my recommendation based on 17 years of tracking this: If you’re keeping the vehicle past 100,000 miles and the belt is original, replace the tensioner and inspect idler pulleys at the same time. The incremental cost is minimal compared to doing the job twice.